If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Packsys Global, a world leader manufacturer of specialized equipment for packaging, has introduced the new LTR2 side-seamer, the only side-seamer in the world operating with a closed control loop, leading to exceptional process stability. With five years of success in legendary high quality seam technology brought by the LTR side-seamer, now is time for the LTR2, carrying over all the advantages of LTR including INVISEAM®. Among the innovations in the LTR2 are the possibilities for quickly changing the size over capability, as well as the next step in side-seam stability, the “A4S” system.

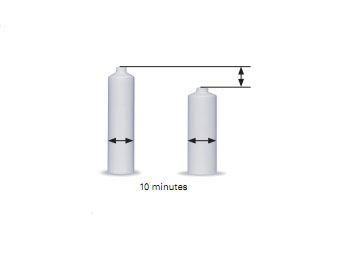

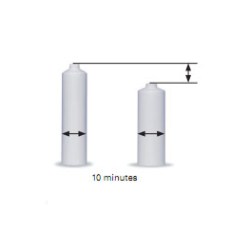

The size part change can be over in 10 minutes. Complete unit can be prepared off line and brought to the machine and exchanged via trolley. Trolley accommodates all size parts (i.e. forming belt, blade take up, etc.) and serves for maintenance and storage.

The new active side seam stability system “A4S”, is a closed loop system: additional sensors do continuously measure the laminate position and give feedback and instructions to machine and web guide controller.

Some of the advantages of the LTR2 are that guarantees stable and consistent seam quality; no additional skills are required to run Inviseam tube quality; and there isn’t any reduction in production ef?ciency for Inviseam as it detects abnormalities and adjusts, rejects, or stops the machine immediately.

It is also an energy efficient machine, since it uses a waterless system for tube ovality prevention. The new LTR2 is able to save up to 40% in air and water and electrical consumption. It also features an automatic splicing of web roll.

All of this advantages result in less waste, less operator influence... and more output!

Technical details:

- Diameter range 19 – 63.5 mm

- Body lenght 60 – 240 mm

- Max. linear speed 36m / minute

- Maximal cuts per minute 150

.jpg)

.jpg)

.jpg)

.jpg)