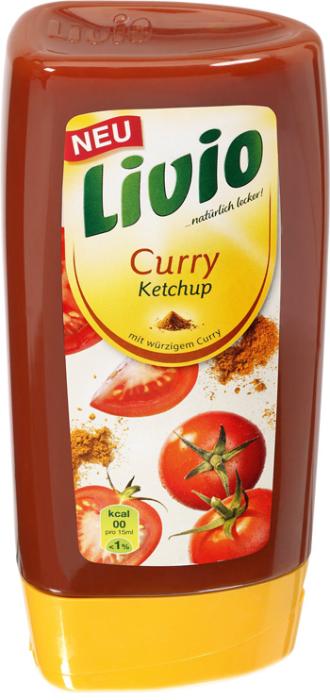

The Livio® brand has held the end-consumer's trust with regard to natural enjoyment for years - the Livio tradition goes back over half a century, with a brand recognition factor of 84% with end-consumers. Now, a valve solution created by Weener that allows precise dosing has been chosen for the Livio sealing cap on Homann premium ketchup.

It was just October of last year that Homann acquired the license rights for the Livio brand for delicatessen commodity groups such as ketchup, mayonnaise and dressings. Livio will once again become more present for end-consumers through the associated expansion of the brand portfolio, according to company statements. Tradition is a major priority at Livio and not simply with regard to the excellent quality of the products. With this new premium ketchup container, Homann builds on the shape of the metal Livio Klassik vegetable oil container. The unique Livio triangular shape ensures especially high recognition on supermarket shelves.

Doing justice to this extraordinary and sophisticated shape with a groundbreaking cap with regard to design and function was the task with which Homann approached Weener.

Controllable Dosage

A valve solution was chosen for the Livio sealing cap for the Homann premium ketchup product that allows precise dosage – an enormous plus in the eyes of the end-consumer, as it does away with sticky, soiled exit openings and their unattractive appearance on the table. The flexibility of Weener plastic valves ensures that dosage characteristics can be precisely adjusted – from drop-by-drop to a defined stream. The geometry and the slot of the self-closing valve are responsible for the regulation of the released product.

The special technical demands on the technicians and engineers at Weener also included the orientated opening of the cap. The active hinge, which is located on the side, guarantees a free view of the opening and allows precise dosage of the product by the end-consumer.

The distinctive outer contour of the container required a precisely defined screw-on position for the cap. The sealing method chosen by Weener for this application ensures that the cap still seals reliably after the foil seal has been removed. The foil seal is pressed onto the mouth of the bottle after it has been filled with the ketchup in order to perfectly seal it. At the same time, the sealing method developed by Weener guarantees a flawless seal even after the foil seal is removed.

Tough Timing

Weener utilized all the modern engineering possibilities at its disposal simultaneously during the development of the product, leading to a significant reduction in product development time.

Another major challenge in the development of this demanding project lay in the tight timetable. The enquiry from the headquarters of the company in Dissen in the Teutoburg Forest was received at Weener in late summer, and the first retail samples were already supposed to be available by the beginning of October. Weener not only met the closing dates, but also delivered results in the form of an innovative container that fulfilled all requirements.

The new container allows product dosage that is clean, easy and quick while fulfilling high demands on functionality and quality – just what the end-consumer expects from Livio products.

.jpg)

.jpg)