Whether you're running a huge corporation or a small home industry, you put a lot of effort into crafting the best products for your customers. The $532 billion cosmetics industry is a competitive playing field, so you can't afford a slip up when it comes to packaging. Poor design, and low-quality or inconsistent quality materials will affect your sales.

APackaging Group highlights the packaging solutions you can count on to stay on top of your game.

What should be your top considerations when sourcing cosmetic tube packaging suppliers?

Versatility is one of the most important things to investigate when selecting a cosmetic packaging supplier. You want to be sure you're dealing with a company with an innovative mindset and that's up to date with the latest technologies and has the appropriate manufacturing capabilities.

They should also be constantly looking or ways to fine-tune their existing systems and add to them as better methods evolve. Their scale of services must be extensive, comprehensive and diverse.

Stringent hygiene and quality control are imperative in the cosmetic packaging industry. Along with ethical workplace practices, these aspects help ensure that the final product is of the highest standards.

Try to find a supplier that exceeds industry standards for its quality control procedures, rather than meets minimum requirements, at every stage of the packaging production process.

You should also consider that as you'll work closely with your packaging supplier to bring your products to market timeously, you therefore should pick someone you can get along with. Friendly, responsive, and accommodating customer service makes your journey a lot easier, and a lot longer-lasting. Choosing a supplier with a good reputation is the first step in ensuring the best standards of customer relations.

How important are industry experience, design expertise and capability?

No amount of technology and goodwill can compare with the benefits that experience offers. Industry experience is key to ensuring that your supplier is up to date with everything surrounding the packaging industry including regulatory standards, packaging requirements, and trade ethics.

When you deal with a cosmetics packaging manufacturer that has years of experience in the industry, you can feel confident in their know-how when it comes to getting you what you need in a compliant and timely fashion.

You should never settle for anything less than the design you want when it comes to cosmetic packages. The wider the range of designing services that a cosmetic tube manufacturer can offer, the better.

A team of packaging designers should be on hand to work closely with you throughout the process and they should offer guidance about the latest trends and help you craft the type of custom packaging that adds irresistible appeal to your products.

The best packaging manufacturers have a dedicated design studio to mold and print your cosmetic tubes on site.

What design considerations should be considered?

Mold making is important, as custom sizes and shapes are a key aspect of cosmetics packaging. They can help to exhibit brand consistency while also standing out from the competition.

Choose a supplier that offers enough flexibility to not only design and create your perfect custom cosmetic tube designs. You should also make sure they also offer a range of complementary products, like pump dispensers, glass bottles, and dropper bottles. These will come in handy if you decide to expand your offering.

What about eco-friendly beauty packaging materials? What options are available?

Nowadays, customers want more than just good looks from their cosmetic bottles and tubes. They want to know that your packaging is environmentally-friendly too and there are many different options, all with different benefits.

PCR (post consumer recycled) packaging comes from recycled plastic reconstituted into a durable plastic with a luxurious look and feel. PCR has several eco-advantages such as a very low gas-vapor transmission rate. It's also suitable for recycling over and over again.

Paper packaging is 100% recyclable and fully biodegradable. It's a far better alternative to petroleum-based plastic cosmetics containers and paper tubes are perfect for creating lip balm containers with a high-end appearance.

Bamboo is an exceptionally environmentally-friendly option for packaging. It's biodegradable, compostable, and fast-growing and one of the most luxurious packaging options available.

Sustainable packaging tubes are a huge trend in the cosmetics industry and show your customers that you care about the future of our planet.

Which type of tube is best?

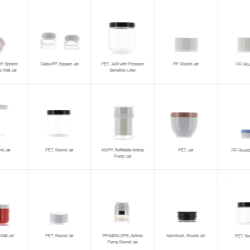

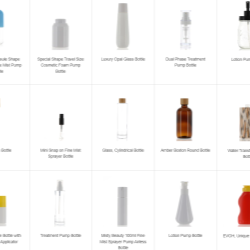

The best cosmetics packaging suppliers have an extensive portfolio of cosmetic tube stock items to choose from either as-is or as a starting point for custom designs.

The two main types of cosmetic tubes are lip balm tubes and lotion tubes.

A lip balm tubes is a type of cosmetic tube is commonly used for lipstick, solid make-up like concealer, and lip balm. They're available in any Pantone color, including matt black, and often feature a twist bottom that pushes the product to the top of the container. Sometimes these tubes are also referred to as 'sticks'.

Some of these tubes come with a roll-on topper which is ideal for liquid balms, perfumes, and lip gloss. Sizes vary from 1/4 oz and more.

Usually, the tubes are cylindrical or oval with a screw top, or flat cap. Lipstick containers usually have an outer case which a manufacturer can design according to your specifications.

Most often, manufacturers make these tubes from plastic, but eco-friendly options like paper are becoming a popular alternative for this type of tube.

A larger version of these, known as deodorant tubes, are popular for sunscreen, roll-on deodorants, and solid perfumes.

Lotion tubes are the most diverse cosmetic tube options, available in a huge range of sizes and designs. These cosmetic tubes can hold anything from 1ml up to 300ml of product.

Polyethylene is one of the most common materials for these kinds of tubes. This material is affordable, lightweight, and easy to use. A wall thickness of around .4 or .5mm is best.

There are two main types of lotion tubes, namely round and airless. Airless tubes are thinner, while the round versions take up more space due to internal air.

These tubes are available with several neck styles... standard thread, short nozzle thread, extended nozzle thread, membrane head thread, top-star...

A standard round top is ideal for products needing precision applications. For hygiene purposes, seals are often placed on the nozzles and a standard or custom cap seals the package.

Lotion tubes are very versatile with many different sizes, shapes, and materials to choose from. They're ideal for skincare creams, body lotion, liquid sunscreen, and face wash.

Which closures are best to use with a tube?

The best-known example of cosmetic squeeze tubes is the old-fashioned toothpaste tube with a small screw cap. Some of the more innovative caps available nowadays include flip-top caps, large round screw-on caps, child-resistant caps, airless pump caps...

Caps with a flat top are much easier to display than the traditional screw type and give your cosmetic product packaging a sleek, upmarket finish.

Should anything else be considered when choosing packaging?

Yes, there are a few more things to think about when deciding on the perfect tubes for cosmetics. These are:

- How will you fill your cosmetic tubes?

- Do the tubes meet your shipping requirements or do they need protective packaging?

- Is the packaging easy to store and display?

- Is there enough space on each tube package for a compliant label?

- Do you have the facilities to sterilize your cosmetic packaging before use?

While comparing tubes packaging suppliers, it's important to choose one who can advise you about these choices and show you examples of what's worked in the past.

Designing cosmetic packages that are difficult to fill or that can't stand up to shipping is a waste of time and money. A great packaging supplier will help you find something that works practically as well as aesthetically.

Turnaround time is of utmost importance in a fast-paced industry. That's why you need a supplier who delivers on-time every time while offering competitive pricing.

A good supplier will guide you through all the red tape involved with export and import, ensuring you get your supplies when you need them. They'll also deal with all the necessary paperwork, like Certificates of Origin and any other trade requirements.

They should include safe, durable and leak-proof secondary packaging boxes by default. Make sure you discuss every detail of this vital aspect when interviewing potential suppliers. Shipping is the last place you want to discover a weakness in your supply chain.

APackaging Group has production facilities in strategic locations across the USA and Asia. That means we can ship your product tubes quickly and efficiently no matter where you're located.

As one of the world's leading cosmetic tube packaging suppliers, we're eager to introduce you to our range of excellent cosmetic packaging options. For more information about our business or products, get in touch or browse through our product catalog.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)