If this is your company, CONTACT US to activate Packbase™ software to build your portal.

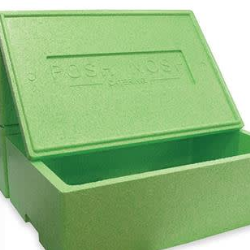

A new checkout concept, centring devices, R- flute® and specific mechanisation systems allowed DS Smith to create an innovative global solution.

Challenge

The challenges were threefold: recoup the space lost to the mechanisation of the packaging boxes, maintain the vertical compression strength (BCT) and stability on pallets despite pre-cuts on the side of the boxes and finally, find a way to reduce the cost and size of the packaging.

Our Approach

We began by studying the mechanisation, palletisation, sales, etc. of existing cases in secondary packaging before selecting a “wrap-around” mechanised solution. The Shelf Ready Packaging (SRP) solution included a patented centring device, an R-flute® and a specific DS Smith machinery. The combination of these technologies helped to reduce the overall costs dramatically, with the bonus of being retail ready.

Results

- Reduction in cardboard surface of 8%

- 50% less wrapping of pallets (857 kg of plastic films saved annually) thanks to 2 mm centring device on the top of each box and corresponding interlocking opening in the bottom of the next box up.

- 35% more cardboard banks per pallet* thanks to introduction of thinner R-flute® (2.2mm vs 3mm) cardboard

- Reduced number of trucks needed for delivery and subsequent reduction in CO2 emissions

- Efficiency of the new mechanization, increasing the packing productivity

*compared to B-flute

The SRP solution brings a number of additional benefits to the retail environment: it is easy to shelve thanks to its intuitive opening (removing the top panel and two forward lateral bands), it offers maximum visibility to consumers thanks to its recognizable base layer, and even in the event of reduced shelf height, the cases are easily reachable. The success of the DS Smith packaging solution was evident when it was awarded a Packaging Oscar in the corrugated materials category. More importantly though, is that the customer was happy enough with the solution to roll it out to other product lines within the group.