Public

Lameplast 3D Catalog

Lameplast Catalog

Lameplast Documents

Lameplast Gallery

Lameplast Locations

Lameplast News

Lameplast Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Lameplast

Lameplast is specialized in the manufacturing of primary plastic containers for the pharmaceutical, healthcare, veterinary, diagnostic, vaccine, skin and hair care and food supplement applications.

Lameplast is specialized in the manufacturing of primary plastic containers for the pharmaceutical, healthcare, veterinary, diagnostic, vaccine, skin and hair care, and food supplement applications.

Founded in 1976, Lameplast has been a leader in developing unit dose and multi-dose solutions for a wide variety of applications.

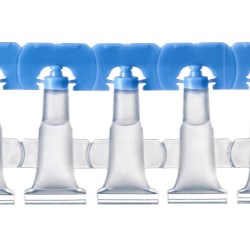

Lameplast offers a complete range of products including single and multi-dose plastic containers, bottles complete with caps and droppers, vaginal washes, enemas, micro-enemas, applicators and innovative and personalized packaging, tailor-made to customer needs.

Each product developed by Lameplast is the result of advanced design capabilities, the use of state-of-the-art technology and a thorough knowledge of the production and transformation processes of all types of plastic material.

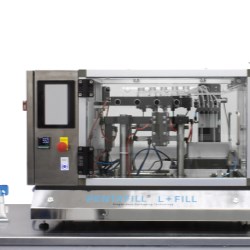

Lameplast can provide its customers with Pentafill™ machines, single-dose plastic container filling, and sealing machines, with the possibility of creating made-to-measure machines as per customer specifications.

Quality standards

Lameplast guarantees the highest possible quality standards at all times : all manufacturing processes are carried out in a controlled contamination environment according to ISO 7 (ex class 10.000) and ISO 8 (ex class 100.000) - ISO standard 14644-1, while rigorous tests and inspections are carried out Lameplast’s Quality Control Department on the entire manufacturing line. Lameplast’s Quality System has been certified according to UNI EN ISO 9001 standard since 1995. The company is the holder of CE mark for Class I Medical Devices.

Vision

Lameplast’s strategy is based on the attention it pays to product quality, service and customer assistance, and looks towards innovation as the drive needed to face future challenges on the market.

Mission

Lameplast carries out all phases of the processes with great flexibility and technological capacity. It is a benchmark for pharmaceutical, medical, diagnostic and cosmetic companies, to which it offers a complete service, ranging from the planning and production of a new primary container, thanks to innovative and personalized solutions, to the finished product and filling technology.