It was apt that during the week-long regional beauty event, Cosmoprof Asia in Hong Kong, Helen Sun, Sales and Marketing CCO (Chief Commercial Officer) at Magnetic Packaging revealed the company's plans for the future. Evolving from its ethos of "turn key luxury packaging solutions" to "customizable dispensing solutions", it's an important time for Magnetic Packaging as the company steers its focus to consumer-centric, customizable dispensing solutions.

What does the focus shift from "Turn-Key Luxury Packaging Solutions" to “Customizable Dispensing Solutions” mean for Magnetic Packaging's customers?

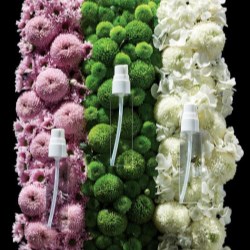

Since the company was set up, 20 years ago, it has always focused on dispensing solutions. At Magnetic we are constantly innovating dispensing systems to ensure that the user has the best experience possible. This is a key differentiation between Magnetic and other packaging companies as well as being a key benefit to brands that have a reputation to maintain.

We are constantly innovating dispensing systems to make sure they provide the best user experience possible and this is the key that marks Magnetic Packaging out from other packaging companies.

Magnetic provides Turn-Key Luxury Packaging Solutions, and most importantly, the company focuses 100% on making its dispensing systems perfect for different consumers and different products.

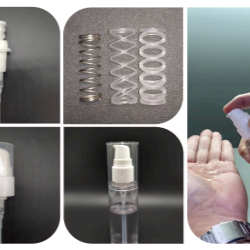

For packaging that incorporates a dispensing system, that system is the "heart of the packaging". The dispenser is the central, integral factor, therefore it is very important to make sure it works well and efficiently, and will continue to do so for the full life-cycle of the packaging.

Through the advancements that we have made and the experiences upon which we have developed over the past 2 decades, we are able to provide Customizable Dispensing Solutions which meet specific individual needs.

We work with a lot of companies both here in Taiwan as well as internationally, and receive regular positive feedback from our customers with regard to our customizable dispensing solutions. The planning is often very concise as it requires a thorough packaging consultancy and professional know-how in order to ensure that the proposal is right, but this is the reason that our customers give us favorable feedback and choose to work with us again and again.

How do you ensure that customers receive the best packaging solution based on the most current packaging trends and technology?

We do a lot of work to ensure that we are at the cutting edge of both trends and technology. We have an annual budget specifically for marketing research in order to gather industrial knowledge and ensure that we know all the latest packaging trends as well as being able to forecast up and coming trends. One particularly important focus of our market research is that of consumer behavior. As we are well aware of what the consumer wants, this means that we can ensure that brands have the best solution available so they are ready to meet their target.

One recent example is the 3-in-1 dispenser which was launched shortly before the week of Cosmoprof Asia, an important event in the packaging calendar for Asian companies in particular, for its leading position. The original concept of the 3-in-1 dispenser was derived from an observation of household cleaning products. The dispenser is based on a sustainable concept to prevent wastage of water and natural resources. The resulting 3-in-1 dispenser saves natural resources offering an eco-friendly solution with precise dosage that the consumer elects.

How does Magnetic create packaging solutions based on eco-friendly requirements?

Magnetic's packaging is not based on one single eco-friendly concept. It's all about the materials and production processes that the company adopts too. It is company policy that everything be hazard-free to humans. The core idea is that packaging production at Magnetic works in parallel for a sustainable and natural co-existence.

When we use POM plastic, for example, for specific packaging components, the production process involves formaldehyde, a substance that is well documented for its dangerous impact on human health. When we run this process we make sure that the raw material and every other material involved in the process are safe and harmless. The way in which this is achieved is through the contracting of professional labs (SGS) to perform a toxicological risk assessment. It's California Proposition 65 with tests to check for 19 types of heavy metal and 16 types of phthalates. Every production process at Magnetic has to be qualified according to several different standards for regional laws, including RoHS (Restriction of Hazardous Substances Directive).

What does it take for Magnetic packaging to stay sustainable in its business and in its packaging solutions?

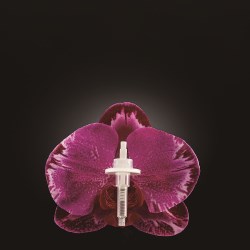

At Magnetic, the "user experience" is always fore mount and the primary consideration when providing the solutions to develop and deliver a project. Packaging needs to function well as a medium to hold the product and offer the user the best possible user experience. This is the one and only direction we have at Magnetic and ensures that the business is sustainable and also continues in its growth. We make sure that every part of our design and production be practical for daily usage, which in turn ensures our company's credibility as a packaging supplier and the necessity of our product offering.

How does the company ensure the best dispensing solution for a customer?

It's all about asking the right questions! For example, when a customer is looking for make-up packaging for liquid foundation, we need to know the customer's preferred material choice, the output requirement, budget, lead time, and many other project details. In order to make sure things go forward in the right way, we use "New Project Development and Assessment" as standard operating procedure when we begin a new project with a client. This ensures that all requests made are included as well as price and lead time considered and accessed. It saves a lot of time on going back and forth, and most importantly, it prevents mistakes. By following this process, we are able to avoid a possible disastrous result.

The process works well and we have many successful projects. This year in particular, we have received several tailored projects from Chinese companies. But, the process is the same, whatever the project, wherever the customer is located.

What are the next steps for the company?

Visitors to Cosmoprof Asia noted that we had a new-look display this year. We used the event to springboard our new focus on dispensers and dispensing systems. Magnetic's core service and best feature is its dispensers. The company started as a dispensing system provider and it is what we do best.

New product development at Magnetic will focus on dispensing solutions and we are also looking for a new production site to support our growing business.

We have been busy in the expansion of the production area and in updating our facility where we recently installed a clean room to make sure the entire process is dust-free. In 2018, we will look for a production site elsewhere in the Taichung Industrial Park in order to ease pressure in production.

Magnetic also recently announced its important decision of its confirmed cooperation with regional distributors in China, Europe and North America. This decision is not something that will change Magnetic's current business operations with existing clients, rather it will improve the company's local service offering. Our sales team is working closely with local distributors internationally and we can foresee a prosperous era coming for Magnetic Packaging.

What’s the difference between Magnetic's sales team and its distributors?

The benefits we can get from local distributors are many as we will be able to maintain better our business relationships. This means that our sales team will be able to concentrate on specific deals while local distributors manage client communications and responses without the barriers of time or cultural differences.

Magnetic can therefore focus more on product development as distributors are entrusted to provide immediate local service, to answer customer's questions and solve any possible issues.

What is next for Magnetic in packaging design and next trend development?

I've been working at Magnetic for 9 years, and there are so many changes that I've seen during this time. The most important evolution is how consumer behavior has shifted, and how as a packaging solutions supplier we have developed different solutions to fit changing market needs.

When the packaging isn't right for a particular product, the result is unhappy consumers. That is why consumer benefit and the best possible experience of the packaging is at the center of the company and its products. It's a mutual benefit for consumers, brands and the company. Through this mutual benefit, our business is sustainable, and by ensuring the fulfilment of this requirement the growth of the company into the future is certain.

This is particularly relevant to my position at Magnetic as Sales & Marketing CCO (Chief Commercial Officer). I develop new business and maintain business relationships with customers in addition to coordinating with the factory manager regarding daily production to make sure that production runs according to the plan.

The change to Magnetic's company structure is key to its growth. We consider ourselves "a company with no secrets" as we are very open both internally and externally.

We also invite schools to visit us for a closer look to our factory. It's important to help students understand how theory be executed in real life as well as inspiring the next generation to join our team. This open-minded attitude to share information enables us to stay at the forefront of innovation and creativity.