If this is your company, CONTACT US to activate Packbase™ software to build your portal.

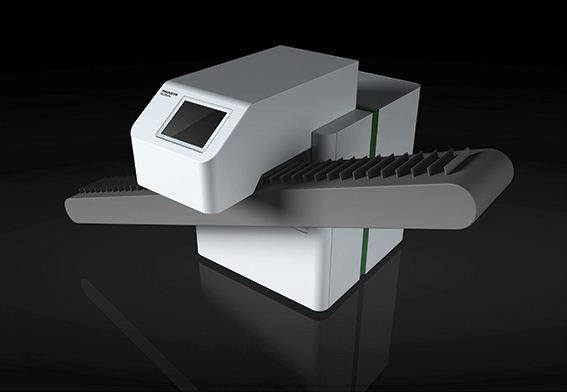

The market trend is for aerosol cans with more shape. To achieve this, more necking stations are required. By moving the camera inspection station out of the necking machine space is created allowing more stations for the actual necking process. PackSys Global has developed CIM, a compact neck inspection unit for aerosol cans on the outfeed conveyor of the necking machine.

The common market solution places the inspection camera directly onto the necking machine outfeed conveyor, which results in less accurate can positioning. The can is not perfectly aligned parallel to the camera and the slightest difference could lead to faulty inspection quality results. Consequently, the operator is forced to reduce the sensitivity of the camera settings to a level where unaccepted defects could pass the inspection station without being noticed.

The new CIM compact neck inspection unit from PackSys Global is located on the transport system between the necking machine and packing station. It is far more superior to traditional systems and accommodates a dedicated handling system for the cans by stabilizing the product in position. This ensures the vision system properly executes a reliable inspection at constant high production speeds.

The upper part of the can is freely positioned in front of the camera, which means no holders or any other parts are reflecting the light that could lead to different color shades on the camera image.

Different languages can be selected on the touch screen panel as well as the camera function and settings if used in combination with a TEMA camera system.

Designed to handle the full range of diameters and lengths with only a few diameter-related size parts required, the compact CIM unit can be retrofitted onto necking machine outfeed conveyors and operates at production speeds of up to 250 cpm. The inspection unit is operator friendly with its one touch screen for both the machine operation and inspection overview.

Furthermore, a state-of-the-art fully automatic vision system can be offered together with the CIM unit. Thereby enabling can makers to use their existing camera inspection systems for which the CIM unit can be customized accordingly.

PackSys Global's new CIM compact neck inspection unit for aerosol cans enables can makers to be ever more in control over quality and performance, while meeting all industry standards.

.jpg)

.jpg)

.jpg)

.jpg)