Public

Packaging Decorations

Preco Corporation 3D Catalog

Preco Corporation Locations

Preco Corporation News

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Preco Corporation is located in Osaka, Japan and has more than 30 years of experience in the surface decoration industry supplying 100% Custom-made Heat transfer and Hot-stamping foils.

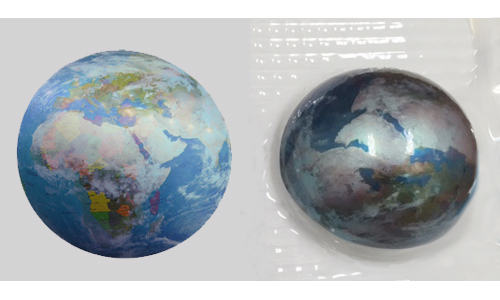

Heat Transfer Film (Foil) is decorative motifs or decals which are pre-printed on the carrier film. Glue and Protection agent are also pre-printed, and it is decorated by Heat Transfer Printing Machine with heat and pressure in single step. Heat Transfer Film can be printed on plastics, and glass or lacquered materials if you apply special pre-treatment.

100% CUSTOM MADE

Heat Transfer Film is 100% custom made under customer's requirements, such as design, size and application. To make the most suitable foil, we always request our customers to test some foils in advance to check the resistance, machine and production adjustment. Through this prior confirmation and checking, we guarantee trouble-free launching of your new products.

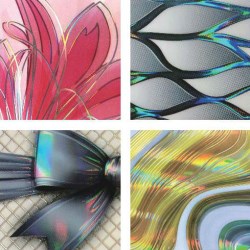

VARIOUS VISUAL EFFECTS

Advantage of Heat Transfer film is not only its easy operation, but also the variation of decorative finish in one process. Varieties of surface finish can be realized by gravure / screen printing methods such as following examples (*Multiple combinations are also available):

- Multi-colored high quality print up to 11 colors

- High definition and photographic picture image

- Small and fine letters

- Metallization by real Aluminum, Tin or Chrome made by Vacuum evaporation

- Half Metallization

- Metallic colors

- Frost (Matte) finish or combination of Matte/Gloss finis

- Smooth Gradation

- Pearl / Polarized Pearl and Polarized Metallic colors

- Glitters

- Transparent and translucent colors

- Combination of multi-finish

- More effects: Having long experiences in Building material printing, we can also realize Wood, Brushed Hairline, Carbon fiber, Celluloid or 3D look-alike images by Gravure Printing which could make your products look like made by real materials.

PRINTING METHODS

We would exploit characteristics of each printing methods. Not only just one printing method, we can apply different printing methods so called "Hybrid printing" such as Gravure + Silk Screen, Silk Screen + Digital..etc.

GRAVURE PRINTING

SILK-SCREEN PRINTING

DIGITAL PRINTING

COATER PRINTING

EASY HANDLING

As motifs, Glue (to attach the motif on the object) and Release (for surface protection) layers are all pre-printed on the film, decoration can be made in just one step. Operation of Heat Transfer Film is much easier compared to other printing methods such as direct printing or pad printing.

Print just in one process:

Clean Operation

ENVIRONMENT FRIENDLY

No need to mix’n blend inks, clean the machines after use, or wait till motifs dry:

Heat Transfer Film is a “Dry” printing method. Just set up a foil roll on Heat transfer machine, switch on and see motifs printed one after another with heat and pressure at high speed. Please also note that no toxic solvent or agent is used on the production. All materials used in our Heat Transfer Film are in conformity with EN 71 Part 3 or other safety regulations (please check with us for details).

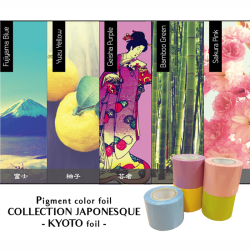

Hot-stamping foil is a decorative endless film (pigment colors, glossy or matte metallic colors, Aluminum/Tin/Chrome metallization, Hairline finish, Hologram, etc.). It can be printed with heat and pressure by engraved metal die, rubber die, silicon rubber die..etc. of your design with Hot-stamping machine.

COLOR VARIATIONS

We have a variety of Hot-stamping foils for your physical + visual requirements. We have custom-made Hot-stamping foils also and we make equivalent colored hot-stamping foils referring to your color sample or Pantone colors.

IMD (In-Mold Decoration) is composed of pre-printed motif, glue and release layers on PET carrier film just like Heat Transfer Film. IMD Motif is decorated at the same time of injection molding of plastic resin while Heat Transfer Film is decorated on finished objects. It is one of the latest and most effective decoration methods for 3D shaped products such as automobile and consumer-electronics parts. Decorating at the same time of the injection molding process, motif becomes a part of the object and no need to worry about adhesion.

The idea of IML (In-Mold decoration Label) is very similar to IMD film. It is also decorated during the injection molding process and only difference is that IML is cutout label while IMD is printed on rolled based film. IML is popular for food/ beverage industry, personal care products, etc.

ADVANTAGES

Safe and environment-friendly

IMD/IML is safe and environment friendly decoration. It can be a replacement of lacquer, spray or any other coating method.

Low emission process (environment friendly)

A dry, solvent-free process assures you low emission production process.

Realization of 3D decoration

Direct transfer of motifs to 3D shaped objects.

High productivity

Simultaneous injection molding and decoration process bring high productivity (and high physical resistance).

APPLICABLE OPTION

We can also print UV hard-coat layer on the film. By setting up an optional "UV Curing unit" on your machine, UV coating can be made at the same operation.

By printing 2 layers of different designs on a single film, the bottom layer is hidden by the top layer, and appears only when LED lights are on just as shown left.

The top layer can be Wood grain, Hairline, custom-design or all over color such as Mirror finish or Piano Black…etc. Design or application is flexible.