Public

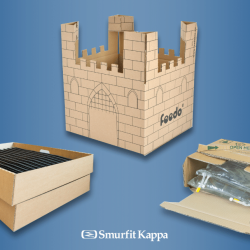

Smurfit Kappa Catalog

Smurfit Kappa Gallery

Smurfit Kappa Locations

Smurfit Kappa News

Smurfit Kappa Videos

Subsidiaries

Saxon Packaging

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Smurfit Kappa has been at the forefront of sealant and adhesive packaging for over 35 years. Composite paper cartridges are just one way we’re continuing to help manufacturers boost sustainability and delight customers with the primarily natural-packaging format.

Here are 3 reasons why you should consider making the switch from traditional plastic to composite paper cartridges:

1.Composite paper cartridges are more sustainable than plastic

If you’re looking to boost your environmental credentials, these are an ideal replacement for traditional plastic cartridges. They’re made from FSC-accredited papers and tinned steel, with just 10% of the cartridge being plastic.

They also break down much faster compared with standard plastic cartridges which take up to 500 years in landfill sites.

2. You can use your existing filling machines

Filling machines are expensive and difficult to replace. That’s why these cartridges work with your existing equipment – so it’s quick and easy to make the change to composite paper.

The process of filling these cartridges is exactly the same as for your plastic ones. They also fit into pre-existing and widely used skeletal guns, to allow easier access in tight corners and spaces.

3. You have a range of options to meet your different product needs

You have great flexibility with our composite paper cartridges. We offer a range of fill volumes, including 310ml, 350/380ml and 900/ 1000ml, [we can also look at 600ml, if required].

Choose from 2 internal diameters: 47mm and 66mm. For the nozzle, there’s a choice of a 75mm fixed spout or a 20mm spigot top for use with your own hanging nozzles.

You also have a variety of print options, so you can offer products with the quality and branding you need. Offset litho printing gives you high definition with up to 6 colours, and there are additional decorative options to enhance your branding on these cartridges.

Get in touch to discuss your specific needs – in terms of specification and sustainability

Smurfit Kappa has a long history of innovation and quality. Our composite paper cartridges are one way we’re helping sealant and adhesive manufacturers leverage those benefits while boosting their sustainability credentials.

.JPG)

.jpg)