Public

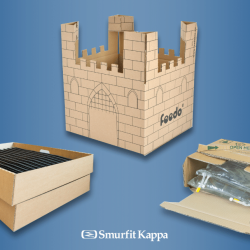

Smurfit Kappa Catalog

Smurfit Kappa Gallery

Smurfit Kappa Locations

Smurfit Kappa News

Smurfit Kappa Videos

Subsidiaries

Saxon Packaging

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Making sure your products are properly protected is crucial. The right packaging will not only protect your products during transit and in stores but will tempt consumers to try your tasty products. Whether it’s biscuit tins or chocolate boxes or any kind of beverage, here at Smurfit Kappa we are specialists in producing paper packaging and we have helped thousands of businesses pick the right packaging options for a wide range of products.

Cushion pads are a popular choice among our clients, particularly for packaging chocolates, biscuits, beverages, and all kinds of confectionery goods. When you look at using cushion pads for your products, you will likely come across the choice of 3 ply or 5 ply. It’s important that you choose the right option. However, knowing which is best for your products isn’t always easy. In this guide, we share everything you need to know about 3 ply versus 5 ply cushion pads.

What Are Cushion Pads?

It is likely that you have come across cushion pads in your favourite box of chocolates or a fancy tin of biscuits. Cushion pads are a way to provide protection for various products to make sure they reach consumers in one piece. They are usually made from a combination of glassine and Kraft paper. Cushion pads are made up of a few layers, varying between fluted material and sheets. This is how the cushion padded protection is created and most packaging manufacturers offer 3 ply and 5 ply options.

What Is the Difference Between 3 Ply And 5 Ply Cushion Pads?

The key difference between 3 ply and 5 ply cushion pads are:

Depth:

The main thing to note when comparing these two types of products packaging is the different depths. 3 ply cushion pads are usually around 2.5mm to 3mm thick, compared with 5 ply which is 4mm thick.

Material:

Both types of cushion pads are made up of your choice of materials and there are various options to choose from. However, the amount of these materials differs between 3 ply and 5 ply. With 3 ply, there is a top layer, then a flute layer, and then a bottom layer. 5 ply cushion pads have a top layer, a flute layer, a middle layer, another flute layer and then the bottom layer.

Price:

The price of a cushion pad will depend on the materials chosen. Generally, the middle and flute layers are created from Kraft paper in either black or bleached. The top and bottom layers are then produced from high quality materials like glassine for a nice finish. There is the option to have all layers as Kraft paper in order to save money. 5 ply cushion pads are always going to be more expensive than 3 ply, simply because more material is being used.

Protection:

Both 3 ply and 5 ply cushion pads offer protection for products. 5 ply provides enhanced protection for delicate items because it is thicker and sturdier than 3 ply. Some food manufacturers choose 5 ply over 3 ply for added protection, while others choose it because it provides a more high-end and luxurious feel.

Tooling and Artwork:

Unlike some food contact packaging options, tooling and artwork is exactly the same for both 3 ply and 5 ply cushion pads. The price of this will remain the same for both and only changes depending on the size of the cushion pad and your artwork requirements.

Why Choose Cushion Pads For Your Products?

Cushion pads are super versatile for various kinds of food and beverage products and are particularly popular in chocolate boxes and biscuit tins. At Smurfit Kappa, we can produce 3 ply or 5 ply cushion pads in standard black or white papers, but also provide the option to have artwork or flood colours on your top layer. When you choose our cushion pads, you are choosing packaging which is 100% food contact safe and made from 100% virgin material which is fully recyclable.

Cushion pads are a much more environmentally-friendly solution than flow-wrapped tray products, helping you to reduce the amount of plastic in your packaging and helping your business do it’s bit for the planet.

.JPG)

.jpg)