If this is your company, CONTACT US to activate Packbase™ software to build your portal.

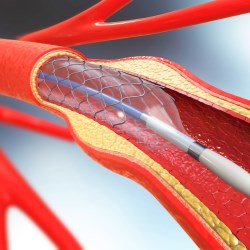

Colorite, a Tekni-Plex business, is announcing a significant expansion of its Cellene® thermoplastic elastomer (TPE) compounds for healthcare and a wide variety of other applications. The company is adding 12 grades to its previously-available 28 TPE formulations.

“Changes in regulations and market conditions are prompting medical device manufacturers to look for solutions via other materials. The Cellene® TPE compound line is ideal for medical device manufacturers and others looking for alternatives to PVC, phthalate-plasticized compounds and various rubber materials,” said Heath Schmid, director of business development, Colorite.

“The line expansion will assist in reducing the development cycle and provide manufacturers with greater options to obtain the durometer rating required for their applications.”

Cellene® TPE compounds are available in four series: 1,000 (extrusion grades for IV therapy with high clarity, improved bonding and kink resistance); 2,000 (injection molding and extrusion grades targeting cost-driven IV therapy solutions; 3,000 (injection molding and extrusion grades for general purpose healthcare, foodservice, caps, liners, gaskets/seals, syringe stoppers, profiles), and 4,000 (injection molded grades for high-clarity applications such as drip chambers.)

The compounds are formulated to be silicone, latex, phthalate, halogen and PVC-free using FDA-compliant raw materials to meet USP Class VI and ISO 10993 standards.