If this is your company, CONTACT US to activate Packbase™ software to build your portal.

This is Ilhaplast's first year on Webpackaging, and we're getting to know each other. What exactly does Ilhaplast do?

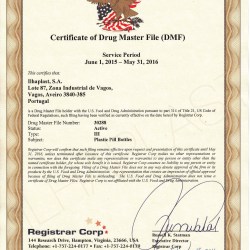

Ilhaplast is a primary, plastic packaging manufacturer headquartered in Portugal. We operate within two primary business areas: packaging for pharma and food supplements and for personal care products. We are particularly focused on the pharmaceutical industry and related markets like nutraceuticals or medical and surgical devices. Most of our work is performed using one of four manufacturing processes. We have machines that take advantage of injection blow molding (IBM), extrusion blow molding (EBM), direct injection molding, and silk screen printing. All work is performed in state of the art production facilities that are fully compliant with a number of international standards.

That sounds like a lot of simultaneous work, how big are your operations?

Well, I would say we're a rapidly growing SME. Our capabilities and manufacturing quality have been recognized quite positively by the pharmaceutical industry, especially in the Iberian region where we primarily operate, but also in central Europe. We're located close to Aveiro, about 90 kilometres south of Oporto, 240 kilometres north of Lisbon.

Being successful can raise the bar a bit. How is Ilhaplast coping?

Well, whenever you're a leader in your field, it tends to require more responsibility, to ensure you consistently remain at the forefront of your sector. We have to be attentive and vigilant and absolutely prepared to meet any new requirements that emerge in the industry. We have a lot of clients, and our customer base is mainly composed of industrial users of our items as primary packaging. We also work with distributors and agents throughout our target markets.

Then, what are some of the challenges or barriers Ilhaplast faces in its chosen markets?

Strategically, the biggest challenge we've recognized for the next few years is spreading our portfolio out to encompass a number of customers and regions, especially considering our goal to increase sales in Central Europe. We are constantly increasing marketing and commercial activities, like attending international shows within our target markets, and expanding our portfolio. Those are some of the ways we intend to overcome these challenges.

You just mentioned shows as part of your plans, which ones will we be able to see Ilhaplast at in 2016?

We'll be at most of the major shows related to the pharmaceutical industry in Europe, especially this year's CPhI/ICSE and Pharmapack. I'm sure others will pop up.

When you visit a show, what is your primary goal? I mean, is it to scope out the market and do reconnaissance? To draw new business contacts?

I think it's a bit of everything. In order to be in business these days, you need to be out there, get your name out in the market. It draws new business and it gives existing customers confidence that they're working with a top notch market leader. We work with a wide variety of firms, like Avizor, Chemo Group, Almirall, Catalysis, Anona Group, OM Pharma, Medinfar Group, Ynsadiet, Vygon, and many others.

What sort of products does Ilhaplast sell to these firms?

Most of the standards found in the pharma space. We make pill bottles, boston rounds, all sorts of containers for speciality pharma products. We're always willing to take on special jobs should a company require something a bit more exotic

What changes has Ilhaplast undergone over the last decade?

In 2008, we moved into our current and better-equipped facility. It was quite a big moment for us, it meant we could upgrade our production lines, take on more orders, and generally continue our growth unimpeded. In 2010, we were able to change our legal status to that of an "S.A." So, once we'd gotten our space and legal requirements taken care of, we moved on to equipment and in 2013, we incorporated injection blow molding as a process and we installed a level 6 clean room in order to offer more services to pharma clients.

Have those changes proven fruitful? I mean, have they done a lot for the firm as a whole?

I think change is necessary and ongoing. You can't just make a change and sit back and coast, you have to keep on top of those changes. Currently, we're experiencing double-digit growth, but making sure that it's sustainable. Because of that, we are once again in the process of increasing our facilities and production capacity by acquiring new and more advanced machinery, mostly fully electric equipment that has been especially prepared to be integrated into clean rooms. We want to make sure to keep our carbon footprint down.

Finally, Orlando, what new items or services is Ilhaplast releasing soon?

We already have customers that offer products designed to clean and maintain all types of contact lenses. We also work with many that produce artificial tears and other solutions for dry eyes. Based on their needs and feedback, our first new release in 2016 will be a brand new line of LDPE eye droppers that conform to the same quality standards we have for our other products. Our R&D team has other projects in the works, but they'll be subsequent to the droppers.