If this is your company, CONTACT US to activate Packbase™ software to build your portal.

The Fenix 3P three-lane shrinkwrapper is the fastest model of the full ACMI range. With a capacity of 120 packs per minute, per lane, this machine is suitable for packaging PET bottles and cans. The two most important aspects that ACMI's research & development department have concentrated on in the Fenix 3P are the product selection group and the oven.

The product selection group

The bottle or can product selection group consists of an independent modular reference pin system that can mount two or three of them according to the speed of the machine and the type of format to be processed.

The laning part is made with stainless steel guides equipped with "quick adjustment" systems which may either be manual or motorized. In this section of the machine, ACMI has inserted a new laned bottle handling system that makes it possible to manage a range of bottles that go from a diameter of 55mm to 120mm without the need to intervene from a mechanical point of view. This solution is ideal for those bottling customers who produce a wide range of different formats on the line and require frequent format changeovers.

The oven

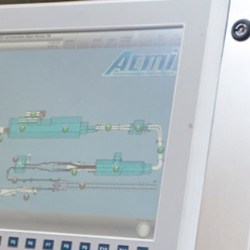

ACMI has supported a number of investments in the development of the shrink-wrap oven in order to achieve greater efficiency and higher quality of the pack. The R&D department focused on three aspects in particular - thermal, air flow and software. All this to obtain a cutting edge and perfectly controllable thermal unit.

This commitment from the Italian company has produced three important results. The first is the containment of the temperature oscillation inside the chamber; the second is related to the temperature oscillation of the oven belt and the third is an almost total reduction of the turbulence around the pack.

Another very important aspect is the modular structure. The thermal unit is divided into one metre modules and each module can be adjusted both from the point of view of the temperature and from that of the air flow. Furthermore, all the resistances inside each module are independent and can be operated individually.

Thanks to these characteristics, ACMI's Fenix 3P shrinkwrapper with three infeeds, is one of the most innovative available on the market.