If this is your company, CONTACT US to activate Packbase™ software to build your portal.

A 1 litre PET bottle line of 36,000 bph

Nestlé Waters, especially through the Perrier brand, is excellent proof of ACMI's ability to handle close business relationships with ethics and professionalism. The beverage multinational has been purchasing machines and complete lines from ACMI for more than two decades, confirming the reliability, the innovative capacity and the quality of the company in Fornovo. At the Vergèze factory, in the south of France, about 50 kilometres from the historic Avignon, flows the famous Perrier water. In this area on the edge of The Camargue Natural Park, France’s most famous water is bottled in a modern factory that can be visited by tourists, too.

Fenix shrink wrapper

Line 30 is a PET line with a production of 36,000 1 L. bottles per hour. At the outfeed of the blowing-filling unit, a series of conveyors and accumulating tables convey the bottles of naturally sparkling water towards the labeller and, then, towards the two-lane Fenix shrink wrapper with a production of 160 packs.

Twisterbox

After applying the handle, the packs are transferred to a higher level by means of a spiral elevator which leads the packs to the fast palletisation system consisting of the matchless 3 module Twisterbox layer formation system which, by preparing the layers continuously and precisely, allows the Faster high level infeed palletiser to form the pallets and transfer them to the stretch wrapper. The stretch wrapper is preceded by a top cover application system ensuring excellent product protection. At this stage of the line, a system of roller conveyors and automatic doors conveys the finished pallets towards the warehouse where they are stored and then transported.

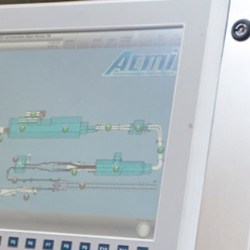

At the Vergèze factory, ACMI managed the design, engineering and commissioning of the entire line as the main contractor.