- This company is no longer trading

-

contact

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Manufacturer Relco has joined forces with Bapco Closures, a leading designer and supplier of closures for the food and drink industry, to unveil its latest indexing induction welding technology.

The modular direct contact induction welding system has been exclusively designed and built for Bapco Closures for the application of its closures on a low to medium speed automatic line. The technology is an easy-to-use piece of equipment designed to integrate into customers' existing filling lines.

The dedicated induction heads (DIH) give uniform repeatable weld performance in a target manner enhancing the leak proof performance of the Bapco Closure technology. The machine can be adapted to weld cylindrical and non-cylindrical closures and containers, as well as being able to handle size change in both height and diameter.

Bapco Closures is using the system to launch the application of its closure technology on PET containers, in addition to the polypropylene (PP) and polyethylene (PE) containers currently available.

Peter McGeough, Co-Founder and Executive Director at Bapco Closures, said: "In this fast-paced packaging industry, it's crucial that suppliers constantly look to develop their proposition to meet the demands of retailers, brand owners and consumers alike.

Our latest partnership with Relco has not only provided us with a platform to launch our new PET dry-fill containers, but also enabled us to adapt our closure technology for a wider food and drink market."

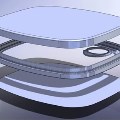

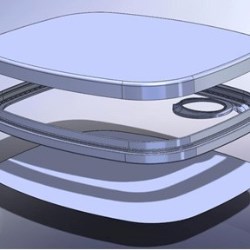

Bapco Closures' unique technology comprises of a two-part injection-moulded closure system that features an overcap and spout with an integrated fused foil laminate. The foil provides an absolute seal that delivers leak-proof packaging and, because the foil, rather than the overcap, traps the vacuum, it is easier to twist off or simply flip open. The Bapco closure technology delivers a BPA /PVC free solution in round and non-round design formats.

Mark Gill, Managing Director at Relco, added: "We're really excited to be working with Bapco Closures in this new venture and look forward developing our new sealing system further with them."