If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Crush Grape is the ecological paper made with by-products of wine processing and this story appears today on the blog by Favini, the respected company for the production of innovative and sustainable graphic specialities.

Favini, in their monthly Crush Story column, illustrate real examples of circular economy practice by describing the life cycle of alternative raw materials used to make Favini’s ecological Crush paper, including Crush Grape. In September, the month which is most commonly associated with the harvest period, Favini retraces the ethical chain of grapes from vineyard into ecological paper.

On the 7th August, on the occasion of the harvest of the first bunch of grapes that officially started the 2019 harvest season, Coldiretti announced that Italy is once again the world leader in wine production, ahead of both France and Spain. The harvest, from North to South Italy, continues until November. [1] Which are the by-products along the vine-wine supply chain and how are they used?

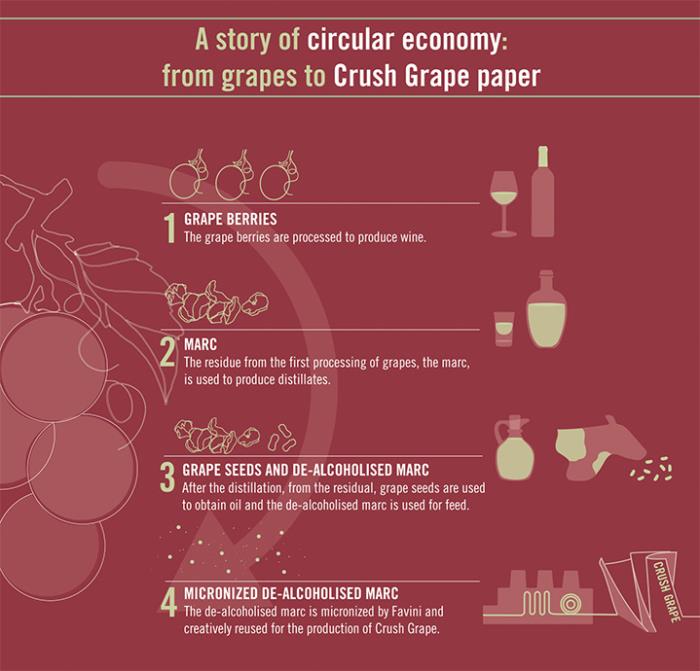

The processing of grapes for wine production generates different types of by-products. These can become an opportunity for the economy and the environment and they are used in different industrial sectors, according to the principles of circular economy.

The waste from wine production becomes an innovative, sustainable and ecological resource for paper production, forming part of an ethical supply chain. During the harvest, the grapes are gathered from the vineyards and then transformed into wine. The residue from the first processing of the grapes is called the marc, a by-product deriving from the grape pressing. The marc is recovered and used to produce distillates.

During the distillation process other by-products are generated: grape seeds and de-alcoholised marc. Grape seed oil is obtained from the remaining grape seeds, whilst the de-alcoholised marc is used as a filler for animal feed.

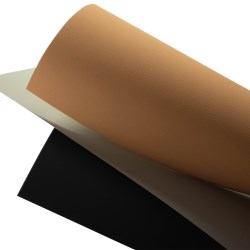

After the different processing steps, the de-alcoholised marc, i.e. the residue deriving from the pressing of the grape bunches and their subsequent production processes, is dried and is then micronized by Favini. The resulting flour is then mixed with water and natural fibres to produce a unique ecological paper: Crush Grape which is made at Favini’s dedicated mill site in Rossano Veneto.

Thanks to Favini’s innovative process, the by-products of wine processing save 15% virgin fibre and become a precious alternative raw material.

At this point Crush paper can be used and converted to create various applications, such as luxury packaging and catalogues, coordinated imagery, labels, invitations and notebooks. These final products will continue on to further lives, if properly recycled.

In addition to the by-product of grape, Favini also use the process residue from corn, lavender, citrus, cherry, olive, coffee, kiwi, hazelnut and almond, for the production of Crush range. These same principles of circular economy have been applied in the paper mill since the 1990’s when they started the making of their patented Shiro Alga Carta, produced with excess algae from the Venice Lagoon and from 2015 with Remake, the up-cycling paper using leather residues.

The Favini R&D lab is always looking for new sustainable solutions in line with the principles of the circular economy, in some cases these are driven by specific requests from companies interested in new papers produced with their own residues. In the wine sector, a case history dating from 2015 is the collaboration with the champagne house Veuve Clicquot. The resulting product was a paper with 25% of the by-products from their own champagne production process. From “cases” of the fruit pulp, to the raw material of luxury packaging for champagne!

The most recent example, launched today at Label Expo, the international trade show for labeling, is the new material developed by Avery Dennison for wine labels using Crush Grape as the facestock, which has a special treatment for wet resistance. This item, offers an ecological alternative to the whole of the Wine & Spirits sector and it is part of a range that also includes Crush Citrus as well as the brand new Crush Barley, perfect for liquors and whiskeys.

[1] https://www.coldiretti.it/economia/al-via-la-vendemmia-10-litalia-leader-mondiale