If this is your company, CONTACT US to activate Packbase™ software to build your portal.

.jpg)

Ishida Europe has opened a dedicated Quality Control Demonstration Centre at its UK headquarters in Woodgate, Birmingham, that showcases the company’s entire range of quality control and inspection equipment including x-ray inspection systems, checkweighers and seal testers.

The new centre enables food manufacturers to see equipment in action prior to purchase and undertake trials for specific products and applications. The Centre also features a special cold room where trials of fresh, frozen and chilled products can take place.

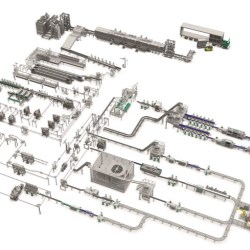

In addition, as part of Ishida’s wider demonstration facilities, visitors are able to view QC machines operating in conjunction with other Ishida equipment such as multihead weighers, bagmakers and case packers, underlining the company’s capabilities in designing and installing complete packing line solutions.

With the extensive choice of equipment available across all ranges – from entry-level to high specification machines - Ishida technical experts are available to provide advice and guidance to customers in the selection of the most appropriate models for their particular requirements.

The company’s wide-ranging experience in all food sectors, including knowledge of relevant regulations and standards, offers an unrivalled applications pedigree and understanding of packing challenges to help identify the best solution to meet specific production and quality control objectives.

“We believe our Demonstration Centre is unique in the number of machines on display and the availability of other equipment to demonstrate complete and integrated lines,” comments Ciaran Murphy, Ishida Europe’s Business Manager EMEA – Quality Inspection Control.

“The facility gives customers the opportunity to ‘try before they buy’, discuss their requirements in detail and undertake product trials to ensure they select the right model for their application.”

Equipment on display at the Ishida Quality Control Demonstration Centre includes the company’s IX-EN entry-level and IX-GN high sensitivity X-ray inspection systems, with a range of capabilities in the handling of packaged products, bulk products and outer cartons and cases, along with the specialist dual energy G2 model that can identify small bones in chicken fillets. Checkweighers on show comprise models capable of handling from 150 to 400 packs per minute at the highest accuracy. Leak detection models include the award-winning AirScan for MAP products and QC220 pressure seal tester for packs without gas flushing.

The Ishida Data Capture System (IDCS) for checkweighers and the company’s remote monitoring Sentinel™ software are also available for demonstration, highlighting Ishida’s ability to support the establishment of smart factories as part of Industry 4.0 and IIoT (the Industrial Internet of Things).

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(MR).jpg)

.jpg)