Public

Mecmesin Catalog

Mecmesin Certificates

Mecmesin Documents

Mecmesin Locations

Mecmesin News

Mecmesin Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

As a global brand, manufacturing products for the cosmetics, domestic, healthcare and food industries, it is vital for Reckitt Benckiser, formerly SSL International, to undertake measures to critically assess and guarantee product quality. This also includes the packaging involved in the production and long-term integrity of the product.

The use of flexible packaging, manufactured with welded seals, requires validation tests to define and standardise seal strength and overall packaging manufacturing consistency. Poor quality seals could cause leakage of the product from stresses caused due to production issues and mishandling.

Reckitt Benckiser quality specialists needed to perform various tests including, compressive load tests on particular forms of flexible plastic packaging. This had to take place at manufacturing cells to control in-process verification tests.

Solution

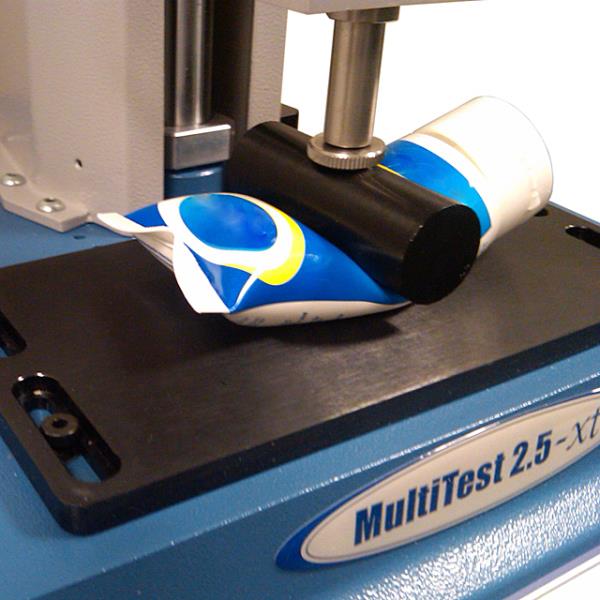

Mecmesin supplied 4 MultiTest 2.5-xt touch screen-controlled test systems, S-beam loadcell and a specially manufactured compression probe.

Following production, a sample is placed on the test system base plate. The compression test is selected and initiated via the user-interface with just two clicks to the touch screen.

As the compression probe is lowered, it places a constant rate of force onto the centre of the sample, thereby introducing a gradual increase in pressure upon the welded seal. Reckitt Benckiser evaluates samples at two force levels, checking seal integrity at 60kgf and 100kgf.

Sample performance is observed 'live', in graphical form, on the display screen and then stored. This, in conjunction with proximity to point of manufacture, enables fast and efficient quality assessments on multiple samples in any given time frame. Reckitt Benckiser initially used the MultiTest-xt to determine benchmarks of quality, through which the company can now quickly identify 'out of tolerance' samples via colour-coded results.

System

- MultiTest 2.5-xt - touch screen controlled test frame rated to 2500N

- ILC-S 2500N

- Special compression probe

.jpg)