Public

Mecmesin Catalog

Mecmesin Certificates

Mecmesin Documents

Mecmesin Locations

Mecmesin News

Mecmesin Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

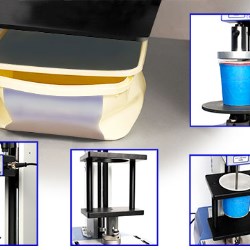

Food packaging made from thermoformed plastics and intended for freezing, requires testing to ensure optimum functionality when closing and sealing the container.

The closing effort of the lid is measured by using a motorised force tester controlled by software together with a custom-designed fixture to hold standard-sized ice cream tubs. In addition the ‘top-load’ crush strength of the container itself can also be tested on the same machine to guarantee it is rigid enough to avoid buckling and spillage when the lid is applied.

Specification

Low temperature conditions and food hygiene standards add challenges to the design and materials specification of this type of thermoformed plastic packaging. Optimal functionality and strength must be achieved, whilst maintaining ease of opening and closing of the container.

A leading food packaging manufacturer required a method of testing the effort to show the lid was fully engaged when closed onto its various ice cream containers. The huge choice of lids and containers available in various shapes, materials and capacities meant that a solution, which provided the flexibility to test all options, was essential.

Solution

Mecmesin configured a software-based force testing system with enough space and load capacity to accommodate the full range of ice-cream containers. EmperorTM software delivered the simple step-by-step programmability to enable the R&D and QA teams to develop the testing criteria unique to their products.

With packaging used by a consumer to store and preserve frozen food, it is vital that the container lid is easy to close and gives a positive feel of being engaged when successfully sealed. The EmperorTM software automatically detects the initial peak force as the lip of the lid is pushed onto the container indicating a successful seal. If this initial peak force is within the specified tolerances the Mecmesin test system gives the operator an immediate pass/fail indication.

To achieve the flexibility in design whilst remaining within the customer’s cost-budget, Mecmesin took full advantage of its 3D-printer facilities to produce a special lower fixture which supports the container evenly around the full perimeter of the lid. In addition the customer benefitted from this approach by investing in extra 3D-printed fixtures, which could be quickly and easily interchanged to test for top-load column crush properties and puncture resistance of the container base.

System

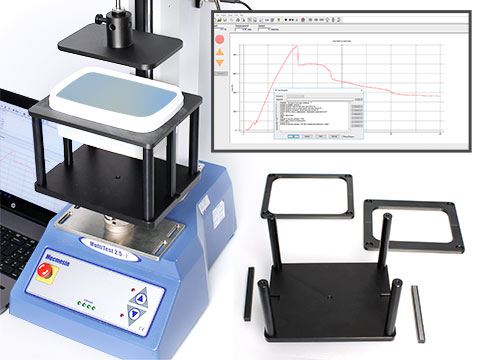

- MultiTest 2.5-i computer-controlled force testing system

- EmperorTM fully programmable force testing software

- Quick Change rectangular and circular compression plates and extended length adapter

- Special lower fixtures for industry standard rectangular tub and tapered cylinder carton designs

Caption 1: Custom lower fixture design securely grips the standard size container and the graph clearly shows the load at the point of lid engagement

Caption 2: With a range of fixtures, the manufacturer may perform a number of packaging integrity tests on the complete container closure system

.jpg)