If this is your company, CONTACT US to activate Packbase™ software to build your portal.

MG America, the U.S. subsidiary of MG2 of Bologna, Italy and a leading supplier of processing and packaging equipment, has been named the exclusive supplier of Axomatic’s lineup of emulsifying equipment and tube fillers for customers in the U.S., Canada and Puerto Rico. The deal gives the Italy-based Axomatic a strong North American sales and service team for its Axomix Undervacuum Homogenizer Mixers, as well as its Axo series of Tube Fillers.

Axomatic’s Axo series is a set of solid, flexible tube filling and sealing machines dedicated to the manufacturing of laminate or metal tubes for pharmaceutical, cosmetic and food applications. Featuring fast and easy changeover, the equipment line offers production speeds ranging from 30 to 210 tubes/min. Product feeders for both semi-solids and liquids are available.

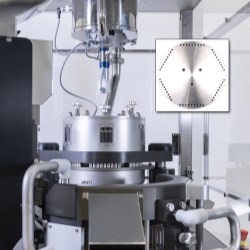

The Axomix portfolio of undervacuum homogenizer mixers are geared to a variety of industries in which cream products are produced, including food, health & beauty, personal care and pharmaceuticals/nutraceuticals. Also known as turbo-emulsifers, the machines feature a special triple coaxial agitation system for the reliable production of creams, milk, gels, balms, lotions, ointments and toothpastes.

The five machines in the Axomix line of emulsifiers span production capacity from R&D through high volume manufacturing; the group’s largest machine can blend up to 6,000 liters of product. Each can be constructed with a bottom-driven turbine, top-driven turbine or both, with the combined action of counter-rotating blades and fast-homogenizing turbines resulting in excellent final emulsions.

The Axomix line’s undervacuum system allows raw materials to be incorporated into the final product without air, and all parts that come in product contact are comprised of Aisi 316L stainless steel. Product heating and cooling phases are controlled by user-friendly software, and Allen Bradley components are available.

A sixth emulsifier, called the MiniMix, is a table-top unit intended for ultra-customized, small batch needs. Finally, MG America also will offer a pair of supplementary Axomatic melting machines. Outfitted with either a mixing anchor or propeller, the melters are heated by diathermic oil, water or steam.