Public

MMC Packaging Catalog

MMC Packaging Jobs

MMC Packaging Locations

MMC Packaging News

MMC Packaging Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

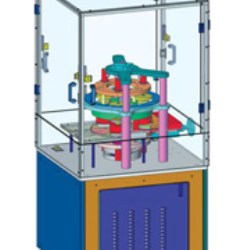

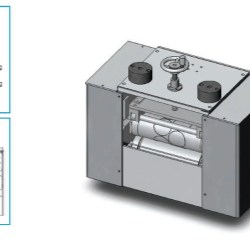

For over two decades, MMC Packaging has collaborated with top manufacturers of child resistant closures. In order to meet production needs, the company has designed and manufactured a complete system incorporating a 24-head, continuous-motion assembly machine and a cap lining machine with 4-across tooling. This turnkey solution can reach a rate of up to 60,000 parts per hour.

The system performs the following functions (in order):

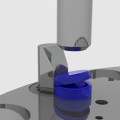

- Assembles both parts of a child resistant closure

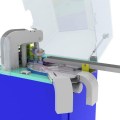

- Cuts and inserts lining (wadding) material into closures

- Detects & automatically rejects grave defects with the MMC-QTVision system

- Loads finished parts into boxes

This assembly system is tooled for a 33mm-CRC, but the assembly machine and cap lining machine are designed to run various cap sizes, including 24mm, 28mm, 33mm, 38mm.