If this is your company, CONTACT US to activate Packbase™ software to build your portal.

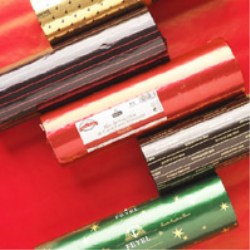

Papiers Paviot

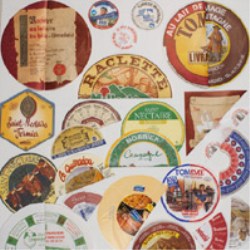

For 150 years, Papiers Paviot has been manufacturing and making innovations in food packaging and bags for the food and organic industries, retail companies, the retailing and distribution industry and packaging distributors.

As a major player in France with a presence in Europe, we monitor developments in consumption and industrialisation methods.

Our clients are some of the leading names in the food industry, distribution, trade, and registered designation of origin and small-scale production.

Health and the Environnement

The environment and health are obvious concerns when working with a natural, biodegradable and recyclable product like paper. We have always been active in four subfields of this area:

Health Packaging becomes a health issue when it comes into contact with food. The Papier Paviot research and development service is particularly attentive to questions of material migration between content and the container.

Wood issues : First of all it is necessary to restate the truth about the major received idea about paper manufacturing.

No! Paper manufacturing does not destroy forests! 99% of the raw materials for the world paper industry come from sustainably managed forests.

Quality and Safety

Working closely with and listening to our business contacts, and anxious to always give our clients added value, we are proactive in our approach to quality and in other areas. The question of quality is therefore as much an industrial issue as one of relations and services, which involve all our partners.

- ISO 9001 Certification : our quality approach is centred on customer satisfaction. It involves company processes and production at our main establishment in their entirety. It guarantees continuous improvement and compliance with our commitments.

- Quality service : working in close collaboration with suppliers and clients, it ensures that procedures are followed and that quality improves in all areas of the company. It controls production, hygiene and the safety of sites and personnel.

- Hygiene and safety : Papiers Paviot has undertaken a HACCP approach to identify the risks and then implement the procedures which guarantee optimal hygiene and safety, which are crucial for production in the food industry. An independent body regularly carries out bacterial checks.

- Staff safety : : in order to reduce workplace risks as far as possible, Papiers Paviot invests in equipment, information and instruction to avoid risky behaviour.

- The next steps : ISO 9001 certification of our Auvergne impression subsidiary and continuous improvement in environmental areas.