If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Romaco Promatic P 91S and PAK 100: bespoke cartoning solutions

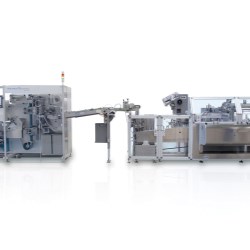

Secondary and final packaging solutions from Romaco Promatic will be presented at this year’s Pharmtech as an overall concept in which ease of use is paramount: the Promatic P 91S intermittent motion cartoner will be shown in an in-line configuration with the Promatic PAK 100 semi-automatic case packer. In the high-speed version, this small footprint cartoner achieves a maximum output of 140 cartons a minute. Its cGMP compliant balcony architecture ensures that no supporting structure is needed on the operator side, thus improving the process visibility and minimizing the risk of cross-contamination. Line clearance can then be carried out smoothly within a very short time. The individual components of the compact P 91S are optimally accessible, not least owing to the retractable carton magazine, making retooling and cleaning much easier. Reproducible and tool-less format changes are completed in under 15 minutes. The versatile Promatic P 91S is hence suitable for a wide range of products and for different batch sizes.

Following the integral transfer of the good packs to the semi-automatic Promatic PAK 100, the cartons are automatically grouped, stacked in layers and packed in shipping cases. The only manual steps are case erection, feeding and removal. An output of up to five shipping cases per minute is possible, depending on the size. The Promatic PAK 100 case packer is extremely reliable and also very simple to operate. The low purchase costs guarantee a rapid return on investment.

Romaco Promatic BIPAK: flexible vertical cartoner

Romaco Promatic’s flexible and versatile BIPAK vertical cartoner is designed to fill the cartons from above. In the standard version the product is fed manually by up to four operators. Optionally the BIPAK can be equipped with an extended feeding conveyor when more workstations are required. Manual feeding gives users extra latitude and is basically suitable for any type of product that is packed in cartons. Automatic feeding with a pick & place unit is offered as an option. Upright products such as bottles or jars, inserts like spoons or pipettes and booklets or trays can be fed very efficiently in this way. Romaco Promatic can supply a range of individually configurable feed options here. The Promatic BIPAK boasts a maximum output of 110 folding cartons a minute with automatic product feeding.

The Promatic BIPAK vertical cartoner can be switched flexibly between continuous and intermittent mode, depending on the application. A simple setting on the HMI suffices. In the execution with manual product feeding, the only changes to be performed on the machine are related to carton size; such a procedure can be easily completed any time since the Bipak is supplied together with the full range of parts needed to run the whole product range that the machine can handle. The very low costs for maintenance are a further defining feature of the Romaco Promatic BIPAK.

Romaco Kilian KTP 420X: powerful rotary press

Cool, fast & clean – these three design features of the Romaco Kilian KTP 420X rotary press are attracting considerable attention among pharmaceutical manufacturers worldwide. “Cool” is a set of measures which enable the temperature in the process area to be maintained at a constant level below 30°C. Special compression rollers, bolts and bearings are used, for example, to restrict mechanical friction to a minimum. At the same time, the efficient cooling of the V-ring seals and drives prevents unwanted heat. The powerful rotary press is consequently ideal for processing temperature sensitive medications such as Metformin or Ibuprofen. “Fast” denotes the ability to speed up product changes: in order to shorten the retooling and cleaning times, the number of product-contacted format parts has been systematically reduced and access to the various components is now easier than ever. “Clean” refers to the optimised hygienic design, which improves product quality and makes the process more reliable. The strict separation between the compaction and service areas prevents tablet dust from entering the machine compartment during the production process. The patented punch bellows moreover protect the tablets from contamination with lubricants.

With a maximum output of 360,000 tablets per hour, the Kilian KTP 420X is classed as a high speed model. The HMI panels of this tablet press incorporate zoom and swipe navigation inspired by modern smartphones. The Romaco Kilian additionally impresses with innovative features on the operator side.

On show at Pharmtech in Moscow (Russia) from November 22 to 25, 2016 (Pavilion 2, Hall 8, Booth B507).

.jpg)