Sixty years since the company was established, the future looks brighter than ever for Virospack. Sales continue to increase and they do so in a noticeable way. This growth is in line with the physical growth of the company. It is the fruit of the expansion plan that Virospack started in 2010 with the acquisition of a new plant and the inauguration of a new office space two years later.

The site of its production plant now boasts a modern infrastructure equipped with cutting-edge technology. Virospack has, in turn, enjoyed boosted productivity, and its customers appreciate the company’s increased ability to fulfil the needs of brands, meeting their requirement with shorter lead times.

The Badalona facilities, next to the Spanish city Barcelona, benefit over 14,000m2 of floor space offering staff a comfortable space and environment in which to work, and the location at which Virospack manufactures and dispatches its droppers to over 20 countries around the world.

Virospack is not one to remain complacent, however, and the firm’s ambitious attitude extends far beyond that of acquiring a new production plant. The company strives to dominate the sector, and to set the trends that others will follow. Competitive offerings attract brands and product personalisation is guaranteed through a specialist approach.

Virospack’s Chief Operating Officer, Isabel Pérez provides an insightful glimpse into the secret behind the company’s success, as the supplier continues to report an annual growth of more than 30% and produces an awe-dropping 70 million droppers a year.

Production figures have doubled in the last two years for Virospack, and numbers show no sign of falling. How has the company managed to keep up with such rapid expansion?

A 9-million-euro investment in the company facilities eight years ago triggered a period of significant expansion, and this growth trend has not paused once since. In total, money injected into the development of Virospack has reached over 40 million euros, and the inauguration of brand-new facilities this year means that the company is confident that its forecast for a production of 100 million droppers annually is realistic.

Why is Virospack now in the optimal position to expand?

Asian e-commerce business and demand has exceeded far beyond the expectations of our clients, necessitating quick adaptation to new market requirements. Virospack has met these demands, and consequently continues to grow.

What changes have been incorporated?

Investment in state-of-the-art technology has been instrumental to Virospack’s journey of adaptation. Flaws in production processes have almost been eradicated, and production speeds and quality have both, in turn, been improved.

Our staff is made up of experienced experts and we maintain the most stringent quality controls. The award of ISO 9001 certification back in 2001 reflects this business ethos, whilst the company this year celebrated its achievement of ISO 14001 certification, underlining Virospack’s incessant efforts towards treating the environment with kindness and adopting a sustainable operating method.

In which new technologies has the company invested?

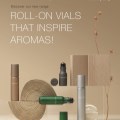

We have made a strong investment in cutting-edge technology, installing a new fully automated production unit which is one of the most modern in the sector. The introduction of laser technology to Virospack's facilities has undoubtedly radically changed the way glass pipettes are made for the company's droppers.

The combination of artificial intelligence and robotics is also essential for all Virospack production processes. In the field of decoration, the development of plasma treatments allows us to provide a greater offering of packaging decoration and metallic colored finishes to our customers, while operating in a more sustainable way.

What sets Virospack apart from competitors?

Virospack’s team of experts is specialized in cosmetic dropper production, ensuring consistent high-quality for all products. All processes are done in-house enabling us flexibility throughout the manufacturing process as well as quality control across production.

What does the future hold for Virospack?

Virospack is currently focused on the integration of new Enterprise Resource Planning software, which will facilitate the company’s move to the automated Industry 4.0. Virospack is also on track to expand via investment in new robotic machinery which functions using artificial intelligence, and a new line of cutting-edge vial shapers will be incorporated into the new glass section soon.

The glass section is a section that is currently being refurbished and will be radically transformed in the first quarter of 2019. The plastic and assembly sections will also be expanded soon.

.png)

.jpg)

.jpg)