- This company is no longer trading

-

contact

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

A G2 multi-packing applicator from WaveGrip, a brand of Berry Global, has helped a leading Canadian beverage company to fully automate its packing line and double its canning output, achieving an exceptional return on investment.

Based in London, Ontario, Black Fly Beverage Company produces a range of ready-to-drink alcoholic beverages alongside its co-packing services, beverage alcohol production and packaging sales. With customers across Canada and the USA, the business was looking to automate its previously manual multi-packing process for its range of cans.

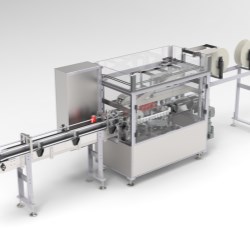

The G2 has been specifically designed for the medium volume multi-packing of cans. At Black Fly the applicator is packing regular and sleek 12oz cans and regular 16oz cans in both four and six-packs, at speeds of up to 245 cans-per-minute (cpm). Operating 24/7, the G2 has replaced a previously manual process and is expected to deliver payback within six months.

“When it comes to the multi-packing of cans at mid-range volumes, our research showed that the WaveGrip G2 is the only practical solution in the marketplace,” said Martin Kamil, Vice President of Finance and Operations at Black Fly.

“Installation was both quick and easy, with the G2 operating straight out of the box. Our multi-packing is now fully automated, delivering significant savings both in terms of output and the ability to re-deploy labour elsewhere in the business. We are delighted with the results we have achieved to date.”

As well as the improvements in production, the sustainability of the WaveGrip carriers and their continued material development played a large part in the decision-making process for Black Fly.

Weighing less than 4g for a standard six-pack and using less material than any other multi-packing solution, WaveGrip is the lightest carrier on the market. Additionally, all WaveGrip carriers are fully recyclable in PE film collection streams and meet current US Packaging regulations.

“Knowing that WaveGrip was a part of Berry Global was another important factor in our selection of the G2 applicator,” said Martin. “We felt reassured that the supply of carriers would grow with our business and through the strength of the wider group, we knew we would have access to the latest material developments and sustainable multi-packaging options.”

Competitively priced, the WaveGrip G2 can run multiple pack formats and significantly reduces downtime with its quick changeover times. With the ability to handle both standard and sleek can designs, the G2 has speeds of up 400cpm for standard, and 325cpm for sleek carriers.

Designed and engineered by manufacturing partner Massman Automation Designs, the G2 is part of the WaveGrip range of applicators, which also includes the G1, an entry level machine capable of speeds of 80cpm and the larger G3 model which can handle higher volume packing over 2000 cpm.

“Overall, we have been extremely happy with our choice of WaveGrip,” said Martin. “From the build quality of the machine through to its consistent 24/7 performance, we would highly recommend the G2 to others looking to automate their multi-packing for cans.”

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)