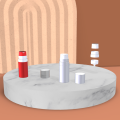

When selling your products both in-store and online, packaging plays a crucial role as it's the first thing your customers will see. It's essential to create eye-catching and captivating packaging to attract their attention. At APG, we provide a variety of decoration capabilities that exceed the usual, including color matching, marbling effects, blind embossing, and more. Want to know how we can take your product packaging to the next level? Keep reading to explore our custom decoration capabilities.

When it comes to branding and product recognition, color is a key factor. Our color-matching techniques provide you with options to create packaging that your target audience will find appealing. We offer two distinct options: the Pantone Color System (also known as PMS) for standard color matching in the design industry, and Pantone Metallic colors for a touch of luxury. With these options, you can specify colors that can’t be achieved through traditional printing, and create consistent brand schemes and designs that accurately represent your digital prototypes.

Our injection molding process employs special masterbatches that give rise to distinct color patterns within your packaging. The unique marbling effect that results from this technique greatly enhances the visual appeal of your packaging, transforming each product in your range into a truly one-of-a-kind offering.

If you want your packaging to exude a luxurious and exclusive vibe, textural effects can do the trick. Blind embossing is an understated yet impactful technique that produces a raised image without the use of ink or foil. This minimalist method adds a touch of sophistication to your packaging, making it an ideal choice for high-end brands. Blind debossing is similar but creates an embedded texture on your packaging, providing a tactile experience that enhances the quality of your product. For a more pronounced effect, registered embossing/debossing combines texture with ink, elevating your packaging to new heights of elegance.

Also, If you are in search of a precise and durable method for labeling plastic components, laser etching is a highly recommended option. This process utilizes a laser to inscribe the packaging, and the outcome is contingent upon the type of polymer employed. Another approach to impart a distinctive texture to your packaging is through flocking. This printing method transfers synthetic fibers via electrostatic force, resulting in a velvety finish that adds both visual and tactile appeal to your merchandise.

Eye-catching and captivating

When selling your products both in-store and online, packaging plays a crucial role as it's the first thing your customers will see. It's essential to create eye-catching and captivating packaging to attract their attention. At APG, we provide a variety of decoration capabilities that exceed the usual, including color matching, marbling effects, blind embossing, and more. Want to know how we can take your product packaging to the next level? Keep reading to explore our custom decoration capabilities.

When it comes to branding and product recognition, color is a key factor. Our color-matching techniques provide you with options to create packaging that your target audience will find appealing. We offer two distinct options: the Pantone Color System (also known as PMS) for standard color matching in the design industry, and Pantone Metallic colors for a touch of luxury. With these options, you can specify colors that can’t be achieved through traditional printing, and create consistent brand schemes and designs that accurately represent your digital prototypes.

Our injection molding process employs special masterbatches that give rise to distinct color patterns within your packaging. The unique marbling effect that results from this technique greatly enhances the visual appeal of your packaging, transforming each product in your range into a truly one-of-a-kind offering.

If you want your packaging to exude a luxurious and exclusive vibe, textural effects can do the trick. Blind embossing is an understated yet impactful technique that produces a raised image without the use of ink or foil. This minimalist method adds a touch of sophistication to your packaging, making it an ideal choice for high-end brands. Blind debossing is similar but creates an embedded texture on your packaging, providing a tactile experience that enhances the quality of your product. For a more pronounced effect, registered embossing/debossing combines texture with ink, elevating your packaging to new heights of elegance.

Also, If you are in search of a precise and durable method for labeling plastic components, laser etching is a highly recommended option. This process utilizes a laser to inscribe the packaging, and the outcome is contingent upon the type of polymer employed. Another approach to impart a distinctive texture to your packaging is through flocking. This printing method transfers synthetic fibers via electrostatic force, resulting in a velvety finish that adds both visual and tactile appeal to your merchandise..

Additional decorations & labeling

Beyond the previously mentioned techniques, we also offer additional decorations and labeling options when creating custom packaging:

a) Hot stamping: Hot stamping involves pressing metallic foil onto the packaging surface, adding a luxurious touch that will grab your customers’ attention. This method is available in many textures and almost any color.

b) Inner/outer spray coating: Spray coating allows you to create a customized color, texture, or design on glass or plastic containers. From frosted looks to soft-touch feels, the possibilities are endless. This process allows you to design truly unique packaging that’s in line with your brand identity.

c) Silk-screen (screen printing): Screen printing is an excellent option for achieving bold, full-color designs on flat plastic panels or cylindrical parts like bottles and jars. As it’s versatile, it’s suitable for printing on various substrates, including glass.

d) Heat transfer (labeling): Heat transfer labeling involves applying a heat-reactive material during the labeling process, leading to high-quality graphics that stick firmly to plastic surfaces. This method is known for its short processing time and exceptional graphic printing.

e) Flexography (labeling): Flexographic printing, which is also known as flexo printing, is a cost-effective method for printing labels. It offers efficiency, flexibility, and consistent results, making it ideal for large runs.

f) UV coating: UV coating involves applying a clear or colored coating compound to plastic parts and curing it with ultraviolet light. This process can be used to add a specific design element to a part of the packaging to make it stand out.

g) Digital printing (labeling): For smaller runs and custom labels requiring photographic-quality graphics, digital printing is an excellent choice. It ensures vibrant colors and precise details, allowing you to create high-quality personalized packaging.

h) Matte varnish: Matte varnish adds a soft and subtle appearance to your packaging design, making it a great choice for packaging with extensive text or text that needs to be read from a distance, as it minimizes glare and reflections.

i) Gloss varnish: On the other hand, gloss varnish is perfect for enhancing colors and creating depth in your packaging design. It makes colors pop and adds a vibrant shine that catches the eye.

To achieve a futuristic appearance for your packaging, consider utilizing electroplating and vacuum metalization methods to create holographic effects. These techniques produce a metallic finish that can elevate the overall aesthetic of your products. In addition, anodized aluminum offers a durable and customizable alternative that can be colored in various shades to create distinct looks for items such as fragrance sprayers and other aluminum packaging.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)