Public

BDMO 3D Catalog

BDMO Documents

BDMO Locations

BDMO News

BDMO Newsletters

BDMO Photoshoot

BDMO Product images

BDMO Products

BDMO Shows

BDMO Videos

Hellyn Photoshoot

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Cardboard boxes can be far more than just storage cartons. Belgian company, BDMO, works in a niche market for luxury packaging boxes and is at the forefront when it comes to presenting and using cardboard boxes in new ways. Sales Manager, Kim Snauwaert, explains why luxury food and cosmetic brands turn to BDMO to fulfil their packaging needs.

BDMO is a name associated with cardboard. What does the company do specifically?

BDMO is a well established company in the cardboard industry with over 25 years of experience. More specifically, we make luxury packaging, adding value to our clients' existing products by providing them with an alluring and tempting packaging that enhances their product. Our company slogan is "upgrading packaging" and that is the foundation of what we do.

The company is located in Meulebeke, in the West Flanders region of Belgium. Due to the boom in business over the last few years, BDMO has expanded and the company now employs about 65 members of staff, plus some temporary people in high season.

What is your role at BDMO and what does the position entail?

My official title is "Regional Sales Manager" and I am responsible for the Netherlands. In addition to sales, I also coordinate design agencies and printing companies in Belgium, and I'm also responsible for BDMO's marketing - so don't be fooled by my job title! My role incorporates the company web site, newsletter, social media activity, our Webpackaging portal, photoshoots and more...

It sounds like you are always busy!

Absolutely! I'm a very busy person, but the company itself has a lot going on nowadays, so everyone on the team is busy!

Why is the company so active right now?

BDMO finalized its take-over of Carir Cartonnage at the end of last year. It's a fairly small company and I was actually based there previously.

We also have a strategic partnership with Hellyn Kartonnage which was announced last February. It makes creative presentation tools like folders and binders. The great advantage for us in the collaboration is that Hellyn Kartonnage makes book covers and there's currently a market trend for boxes that look like books, both with and without magnets. Because of the company's machinery and expertise in the market, it can do this better than us, so through working in collaboration, it makes the outside while we make the box itself.

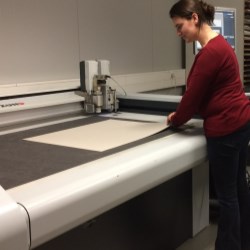

These two events have afforded us many new customers. We were already working at full capacity, so we have since acquired two new box-making machines, one of which that started operation a few months ago, and the second has just been installed. Now, we have nine box-making machines and 2 hot foil machines - the newest of which was installed just before the summer as we had been so busy that we were experiencing a bottle-neck in production!

What does the future have in store for BDMO?

Our mission is to be one of the leading players in cardboard packaging within a 500km radius of our location, so that's basically all of our neighbouring countries - the Netherlands, France, Germany, the UK and here in Belgium too, of course! All our work is done on site at our facility.

Our values are important for all of us at BDMO. When making boxes, we are STERK, which means strong in Dutch, and this stands for Sustainability, Teamwork, Expertise, Respect and Character. For us it is very important that these values are communicated to our customers, and also to our partners as this is an essential requirement that needs to be understood before we participate in any collaboration.

"STERK" values must make the company attractive to customers. In what other ways does BDMO stand out from the competition?

All of our projects are done in-house, so we don't need to rely on anyone else. This provides a great advantage in terms of price, and also makes things easier for our customers as we can do everything for them, and all on-site at our facility.

We make the box, which will include the appropriate printing and decoration finishing - of which we offer hot foil, UV coating, varnishing and more; and in addition to the box, we also produce all of the appropriate complimentary items, whether they be sleeves, inlays, inserts, etc. Anything that is made from cardboard, we will make it! For non-cardboard items like plastic or ribbon, for example, we outsource it locally for our clients and for large orders, we put them in contact directly so they can benefit a better price.

The company also has a BRC-IoP accreditation grade AA. This enables us to supply packaging destined for the food industry and is something that is very important for both us and our clients. Fifty percent of our sales are in the chocolate market and this is an essential accreditation which affords us to work in the market.

The main advantages that customers benefit from working with us are our flexibility, our quality, our price and our innovation. We adapt very easily so that clients get what they want. We also have better delivery times than companies in other regions, such as Asia for example, as we work within a defined geographical area, and can guarantee better quality than many of those suppliers. The labels that we use are made in Belgium as well - something that we have seen is important to European brands when they are looking for a European supplier.

The luxury market regularly demands customized packaging. Are BDMO's projects all customized?

Yes, all of our projects are customized. We don't have any "standard lines" as such. What we do is basically design the shape of the box and provide the outlines so that the customer can coordinate the artwork. Then, our R&D department makes the custom made samples to measure.

Are your boxes only produced for the food market?

Not at all! A lot of our sales are in the chocolate market, but we also do boxes for wine, Champagne and spirits. We also supply boxes for candles; beauty, cosmetic and personal care products; jewellery and watches; gift boxes; corporate boxes, promotional boxes and more.

We work with a lot of well-known brands. In the chocolate market our customers include Neuhaus, Godiva, La Maison du Chocolat and Leonidas for example, and in the cosmetic market we have done many projects with Rituals and other renowned brands. There are world-famous alcohol names and Champagne brands that work with us too.

What innovations in the cardboard industry has BDMO brought to market?

The company is always working on making boxes better and creating new concepts. Two years ago, we created the "table box" - it's a special box that you can slide open and then put the sides down, so that it transforms into a miniature table. The box was designed especially for chocolates so that consumers can share them in a new and creative way.

In 2016, we started working on a plastic closure that could be used instead of magnets. In the case of book covers these closures are more affordable than magnets and we can make them in any colour and personalize them by adding a brand logo, so they look really good! The process began with the design followed by 3D printing of samples so that they could be tested in different boxes. After testing, the next step is a real production run.

We have an excellent R&D department which is always looking for new opportunities and innovative solutions for the market, as well as creating solutions that are requested by customers.

Does BDMO exhibit at packaging events to demonstrate the company's innovations?

Yes. We will be at Packaging Innovations in London very soon and then next year we will be exhibiting at PCD in Paris, Packaging Innovations in Utrecht and Pack&Spirit in Reims. We always have an exciting selection of packaging samples at the events and encourage visitors to challenge us with their cardboard packaging requirements.