For manufacturers and pressure-sensitive tape users, the summer humidity can create concerns about cockling liners. While we cannot stop, or be held responsible for, the forces of nature, we can explain the reason for cockling and offer potential ways to deal with the problem.

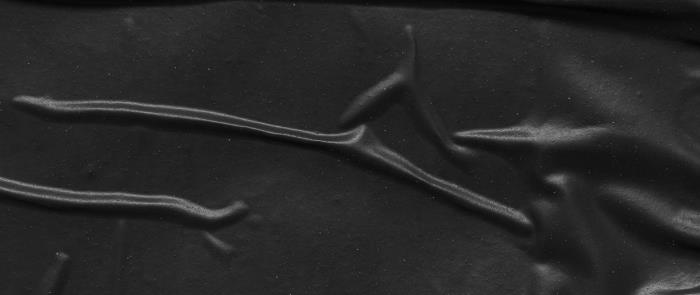

If you have manufactured or used pressure-sensitive tapes with a silicone-coated, densified kraft release liner, you have likely seen cockling. Paper, by its very nature, is an absorptive medium. In high humidity, paper absorbs moisture from the atmosphere, causing it to swell and grow in all three dimensions. This creates the waviness or wrinkling referred to as “cockling”.

All paper-based products cockle to some degree. For example, densified kraft cockles quite visibly while other paper products cockle more discretely.

To help prevent cockling, there are several coatings that can be applied to your paper-based products. Poly-coated liners have a polyolefin (plastic) coat on both sides of the base paper that helps encapsulate and prevent the paper from absorbing moisture. Higher basis weight paper with a poly-coating layer can further protect against cockling. However, these steps do not eliminate cockling all together.

Download and read the complete Berry white paper:

Preventing Cockling of Paper Release Liners