If this is your company, CONTACT US to activate Packbase™ software to build your portal.

CEP Cosmétique

CEP Cosmetic Division: the alliance of injection and extrusion technology.

CEP Cosmetic core competency, the injection molding of plastic, allows CEP to develop sophisticated standard and custom packaging, for Health and Beauty industry. These components are produced in mono and / or bi-injection thru various mold and molding technologies (thin wall, high speed process, stack mold, complex flip top cap, gas assist molding).

Regarding the Tube segment, CEP Cosmetic launched a complete range of injected molded tube in LLDPE and HDPE, for samples size. This unique and proprietary technology has become CEP’s core development strategy, with the use of new polymers and the development of innovative solutions for cosmetic product samplings: the minicep.

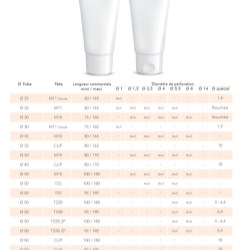

In June 2013, CEP Cosmetic decided to take over a factory of extruded tubes, based in Bayonne. This traditional technology allows CEP Cosmetic to offer the complete range of tube size, from diameter 16 to diameter 50. Different R&D projects have been launched since then, proof of the synergy between the historical savoir-faire of CEP and the integration of the extrusion technology.

The Central element of CEP’s innovation and product development strategy is focused around the “in-house” development of extremely competitive and flexible manufacturing capabilities.

CEP decoration technologies include offset printing, skill-screening, hot stamping & pad printing.

CEP integrates most of its assembly processes in-line, using in-house automation technologies.

PRODUCTS

- INJECTED TUBES FOR SAMPLES SIZE

- EXTRUDED TUBE FOR SALE SIZE FORMAT

- MINICEP ENHANCES YOUR SAMPLING EXPERIENCE!

- INJECTED CAPS AND CLOSURES