If this is your company, CONTACT US to activate Packbase™ software to build your portal.

You also need comprehensive support at every step in the production process from concept through consumption. Crown offers a full array of customer technical and industry support services that can give brands a significant competitive edge.

Customer Technical Service

Crown's Customer Technical Service (CTS) organization provides expert technical advice to maximize customers' production capabilities and to help develop the highest quality finished product. With multiple technical advisors, including the only dedicated ends expert in the beverage can industry, our team provides on-site support for all customer plants across the globe.

Seaming Training

Seaming is the most critical - and demanding - element of a beverage can filling line. Crown offers unparalleled support in all aspects of the seaming process.

In addition to offering state-of-the-art seam monitoring and tooling equipment, we also provide beverage brands with a tailored technical training program on the very latest in seaming technologies. Training programs can be customized to your needs and your location. Our technical service teams offer customized courses in Crown facilities and on-site sessions with Crown service teams and our technical partners can also be coordinated at your own locations, wherever you are in the world.

Graphic Design & Consultative Services

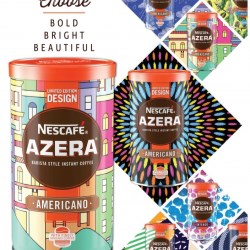

Beverage packaging is an ideal canvas for promoting a brand and conveying marketing messages.

With an endless list of decorative techniques and formats available to choose from, metal packaging is the ideal billboard for promoting brands – it can easily be enhanced to entice consumers with a unique look and feel. Beverage cans are printed with precision and accuracy, representing and supporting brand goals through visual design, and creating a distinctive packaging experience for any occasion or event.

From concept to commercialization, the quality of a beverage can is in many ways only as good as the support of your supplier. At Crown, we collaborate with brands creatively, as well as technically, on a design to achieve the best final output. We have resources strategically positioned around the world, so we’re never far away. With our R&D center in Chicago, Illinois and the team in our Graphics Design Center in Crown's Philadelphia headquarters, along with our new Design Studio in Leicester, UK, brands around the world have access to our skilled service network.

We offer printing recommendations that best support your objectives and achieve the desired visual effect. Making sure that the design parameters are met, and that colors and finishes on the beverage package are exactly as intended, also establishes the groundwork for consistent quality across the entire print run, which builds brand recognition and trust in the minds of consumers.

The first step in any project is to evaluate the graphics and make recommendations relating to the size, quality and colors so that the final package is of the best possible quality. Once the desired parameters have been achieved and the final design approved, a color separation is provided to the printer. Beverage package mock-ups are created so that you can quickly and accurately evaluate how the final design will look when printed on metal.

Our in-house reprographics studio provides insight into feasible methods of turning creative visions into market reality. The studio also provides proof beverage cans, allowing your teams to see their designs prior to the start of full-scale production.

Pilot Facilities

Being first to market with an innovative new beverage product is essential for success in today's competitive marketplace. Lengthy testing processes can often delay product development, as they occupy valuable line space and slow production of existing products.

To help you overcome this challenge, Crown offers access to fully-equipped pilot facilities for beverage packaging and printing technology at our main research, development and engineering centers. At these facilities, we can conduct extensive testing on new beverage packaging products in an environment that replicates the conditions in which beverage cans are filled, processed, used and handled by our customers. These pilot facilities, along with the use of computer aided design (CAD) and modeling, enable us to greatly reduce beverage packaging development time scales and increase the success rate of new beverage products in the marketplace.