If this is your company, CONTACT US to activate Packbase™ software to build your portal.

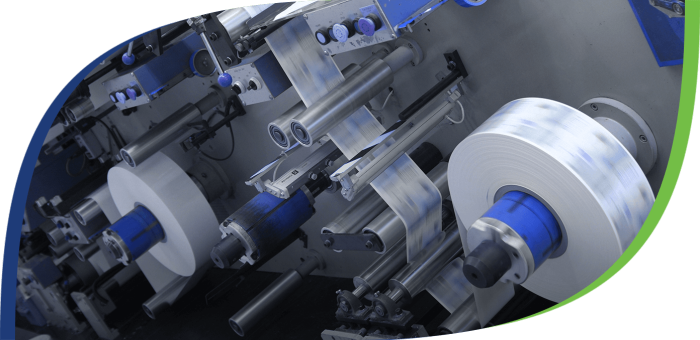

Our standard laminates are composite materials made from LLDPE that form the core barrier of the tube body. They help keep contents fresh and safe with multiple layers of foil. Laminates also help a product catch the customer’s eye from the shelf, with their various available finishes and design possibilities.

We also produce specialty laminates in our facilities in China and India. These include new web structures for aggressive products, or distinct visual elements. We offer our leading-edge R&D and graphics facilities to all our customers for development and testing. With a wide variety of web structures ranging from Aluminium Barrier Laminates (ABL) to custom coloured plastic laminates, we offer something special to every customer.

Aluminium Barrier Laminates (ABL) tubes allow superior light, air and moisture barrier along with reduced flavour absorption in a more durable tube; suitable for pastes, ointments, creams, gels & OTC pharma products.

Plastic Barrier Laminates (PBL) are particularly suitable for packaging that needs to offer strong chemical resistance whilst maintaining barrier properties. Standard laminates are offered in white or natural (clear) ,but specialty custom colours can also be developed.

In addition, EPL also produces a range of custom laminates. Some of these are designed to capture consumer attention in market – such as metallic, iridescent, holographic, soft touch or custom coloured materials. We can customize the laminate for aggressive or hard-to-hold formulations, as well as offer different barrier strengths and thicknesses in web stock to comply with various requirements (e.g.; Five-Layer Laminate Structures, Barrier Layer -either Aluminium foil or EVOH for Plastic laminate, Copolymer / Tie layer and Polyethylene).

.jpg)