If this is your company, CONTACT US to activate Packbase™ software to build your portal.

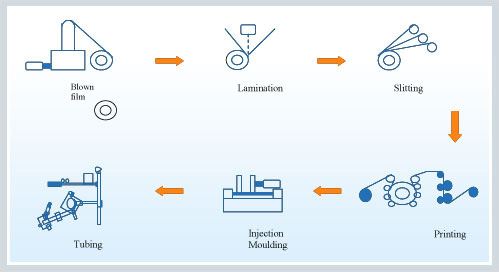

In this descriptive piece, Essel Propack takes the layperson through its procedure for creating high quality, leading tubes. The company's special laminated tubes begin manufacturing with a laminating process that is done in four very specific phases: blown film, laminating, slitting, and printing. Once these printed laminates are completed they are ready for tubing and shouldering.

Blown Film

Laminate is one of the raw materials used by Essel Propack to make tubes. In this process the film and foils are fused together to form a 5-layer laminate. The film is loaded on one un-winder and the foil on the other. Extruded polyethylene is passed between the layers to bind the two layers, which are then fused together. The three-layer laminate thus obtained is then bound with the inner layer (food grade film) resulting in a 5-layered laminate. Film, nylon and foil laminates are produced by extrusion lamination. Mono and multilayer PE films, nylon barriers and aluminum foil form the basic structure of the laminated film.

Laminating

The high-barrier properties of laminate tubes are delivered through the incorporation of thin aluminum foil layer in the multi-layer polyethylene laminate tube body. As an alternative, an all-plastic, EVOH containing polyethylene structure is added. For additional protection of the product, Essel Propack adds, either a roundel or barrier liner to create a barrier by including it in the tube shoulder. This process ensures high stability and provides barrier properties, statutory to pharmaceutical products.

Slitting

The jumbo reel laminates are placed in the intermediate store for curing. Once the curing process is completed, the laminates are taken to the slitting machine. The jumbo reels of laminates are unwound here to be slit into various sizes based on the size of the tube, to match customer specifications. Essel Propack makes use of high speed rotary slitters, which minimize damages to the edges and ensures precise printing process.

Printing

Once laminate is slit to a desired size it is ready for printing. Art works provided by customers are processed using sophisticated technology to enable accuracy with printing of colours and other details on the laminate. The offline proofs are provided to the customer to sample the printing done on the laminate. Essel Propack makes use of the ‘Flexo and Letter Press’ technology for printing. There are 6 to 10 inking stations for different colours. A variety of ‘Nylo Plates’ are prepared for each colour (as per the design), and mounted in the units. When the printing process is completed, different colors are merged together to give the desired design.

Injection Molding

The plants provide injector molding process to create customized caps and closures. The process ensures great efficiency and swiftness. Essel Propack is a breeding ground for operational excellence and innovation. While making closures, particularly when rapid prototyping - a perfect option to test new markets, the company works around the needs and specifications of its customers. Options and solutions are provided to select innovative closures prior to actual production.

Additional capabilities include orientation of closures, snap on closures, tamper evident shrink sleeve brands and specialty decoration such as a metallic layer over shells. Essel Propack welcomes the challenges by creating new ideas and concepts for closures and continues to strive to meet them.

Tubing

The final stage in the complete manufacturing process is the tubing stage, where in the laminate is sealed to form sleeves, shoulder is fixed and appropriate cap applied to the tube based as required by the customer. Essel Propack uses both, ‘Compression Molding’ and the ‘Injection Molding’ processes for fixing shoulders on tubes. A variety of machines are utilised while manufacturing tubes depending on product specifications, volume of production and for developing special features, which may be required to suite customer needs.

Essel Propack machines have auto packers at the end of the tubing lines aid consistent packing of tubes and ensure sterile surfaces. All manufacturing facilities of Essel Propack are supported by highly sophisticated back end utility infrastructure, which helps production to be carried out in a controlled environment. Having adhered to these stringent methods Essel Propack has achieved great success in assuring its customers high quality packaging alternatives -- best suited to the customer specifications as well as the product requirement.

.jpg)

.jpg)