If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Gabriel-Chemie has launched a new range of colour masterbatches for ABS and PLA filaments. The ANS range consists of 20 inspiring colours and some innovative special effects. Sunflower Yellow and Glowing Blue incorporate after-glow effects, Shiny Yellow, Fruity Orange and Shiny Orange are fluorescent and there are also three metallic colours available: Stainless Steel, Traditional Silver and Bling Gold.

The new range offers high colour brilliance and depth, even at low dosage rates and is very temperature stable, some colours even performing up to a maximum of 260° C.

Upon request the masterbatch can also be equipped with Gabriel-Chemie laser marking technology to allow optimal decoration of the final printed objects. This possibility is truly unique in the 3D printing sector.

All Gabriel-Chemie masterbatches meet the appropriate legal requirements and are manufactured in the EU according to ISO 9001 certified processes. Products are supplied with full documentation to ensure that 3D filaments can be fit for purpose.

LIFE-SAVING PROTECTION

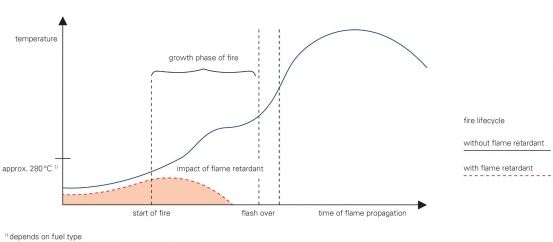

In order to improve safety, many everyday objects are equipped with flame retardants designed to prevent or delay the spread of fire. The list of applications is almost endless, ranging from private and public vehicles, electrical appliances and cables, to furniture, textiles and building and construction materials.

Plastic products require a special focus as they can be ignited by a short circuit, overheating, and other external infl uences resulting in a blazing fire within minutes. Flame retardants can inhibit, or at least delay, the combustion and spread of fire so that valuable time is gained to enable fire-fighting and evacuation measures to be carried out. This in turn, reduces the Chance of serious damage to property or in extreme cases, injuries or the loss of life.

NEW REQUIREMENTS

In recent years, the demands on flame retardants have changed considerably. Environmental

awareness and sustainability are becoming increasingly important factors for consumers. Modern flame retardant masterbatches also need to fulfill increasingly demanding

material requirements.

Gabriel-Chemie Group offers state-of-the-art -products that maintain the same high Quality flame retardant properties, but offer a much improved environmental footprint. Our products meet and even exceed upcoming environmental legislation. The ecologically optimized flame retardant masterbatches delay the ignition of plastics and slow down the spread of flames

METHOD OF OPERATION

In order for a fire to start burning, the combination of a flammable material and the presence of oxygen are required. Flame retardants work by using a chemical reaction to disrupt the interaction between the flammable material and oxygen. They are designed so that the chemical reaction starts with the addition of considerable heat energy. The products of this chemical reaction work both physically and chemically, to reduce the temperature of the flame and to cut off the oxygen supply. The result is effectively a suffocation of the fire that either extinguishes the fire completely, or at the very least, delays the spread of the fire considerably.

Flame retardants that are effective in the gas phase have proved popular due to their high efficiency even when used in low dosages. As a result, the host plastic experiences almost no mechanical or optical degradation and the processability remains virtually unaffected.

OUR FLAME RETARDANT SERIES: MAXITHEN® ANTI-FLAME™

Gabriel-Chemie has been producing masterbatch since 1970 and so the ANTI-FLAME - range is based on a wealth of experience. Our technical support will help to find the right product for your application and can also customize masterbatches to meet your exact Needs.

Our conventional flame retardant masterbatches are based on halogenated agents, are extremely effective in low doses, have a good price / performance ratio and provide good processing stability. Society is however pushing for a substantial reduction in the use of halogens and Gabriel-Chemie is leading this trend with the development of a range of low-halogen and halogen-free flame retardant masterbatches for equipping thin and thick wall polyolefin products. This range of complete solutions enables customers to meet the diverse requirements of the numerous industry flame retardant standards.

Our new low-halogen and halogen-free systems are compatible with widely available UV stabilizers, enabling solutions that provide protection for plastics in outdoor applications such as stadium seating. Our highly concentrated masterbatches are effective in very low dosages meaning that the original mechanical properties of base polymers such as good Impact resistance, high elasticity and low brittleness are not affected. Last but not least our masterbatches are easy to process and enable very flexible colouration.

FLAMMABILITY STANDARDS

Flammability standards regulate the characteristics, test methods and regulatory approvals of plastics in different applications: building, interior furnishing, vehicles, electrical and electronics, furniture, textiles and many more. Worldwide, there are about 700 Standards relating to flame retardants and fire safety testing.

Gabriel-Chemie Group has over 40 years of experience in flame retardants and provides not only products, but also serves as your partner for application and technical support. We look forward to working with you to find the perfect solution for your product and application.

COLOURS THAT INSPIRE

We have been dedicated to specialisation in colours, surfaces and materials for years.

Social trends and associated colour trends are constantly researched.

The selected colours are refined with special effect pigments, which enhance their value.

COLOUR VISION COLOUR CONCEPT

COLOUR VISION® is a colour concept in keeping with the spirit of the times. Through the use of special plastic lens plates and other plastic objects, innovative colours, effects and surfaces are prepared in selected polymers. Experienced trend scouts and innovative colourists actively work on the trends of tomorrow. Together they create a new COLOUR VISION® collection every year.

The COLOUR VISION® series is a source of inspiration for the world of plastics. Brand manufacturers, creative designers of consumer products and capital goods, and Plastics converters rate it very highly for new product concepts.

CREATIVE DIVERSITY INSPIRES

With the analysis of new colour trends from various branches of industry and the consideration of social influences in the market, three new trend themes are devised every year. Each theme is visualised by means of twelve innovative lens plates.

The COLOUR VISION® Trend Box contains 36 trendy colours which are divided into three topics: "Artificial Symbiosis", "Chrome Metallics" and "Plastic Science"

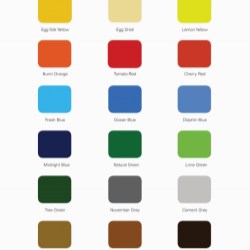

EVERYDAY COLOURS is a range of standard colour masterbatches that combines high quality colouration with the affordability needed for everyday objects.

All 18 colours are completely lead and diarylide-free and food approved according to European Union standards.

High opacity enables good colour coverage to be achieved, even with a low dosage and the colours can be used in both film and injection-moulding applications. The colours are easy to process and are manufactured in the EU according to ISO 9001 approved processes.

MARKING

The laser marking procedure enables permanent markings to be made on plastic surfaces with a visually controlled laser beam. Material optimisation with 2% - 3% addition of laser additives is often essential for achieving an optimal marking contrast. The wavelength required for this, around 1064 nm, can be generated by three different light or diode-pumped laser systems, the neodymium YAG laser, the neodymium vanadate laser and the fibre laser.

MARKING APPLICATIONS

- Lottery codes in beverage caps

- Barcodes and data matrix codes

- Food and cosmetics packaging with logos, scales, product information, expiry dates or decorative designs

- Animal ear tags

- Safety seals

- Security identification/protection from plagiarism

- Keyboards

- Automobile interior and exterior accessories

- Cables and pipes

- Electronic components

- Medical items and laboratory equipment

ADVANTAGES OF LASERMARKING

- Contactless marking of plastic parts

- Suitable for soft, rough, tiered or curved surfaces

- Marking without printing ink and solvents

- No pre-treatment of plastic parts

- Maximum flexibility for complex and fastchanging layouts

- Wear-resistant, chemical-resistant and lightresistant

- Product safety is ensured by lasting and forgery-proof labelling

- Individualisation

- Personalisation