If this is your company, CONTACT US to activate Packbase™ software to build your portal.

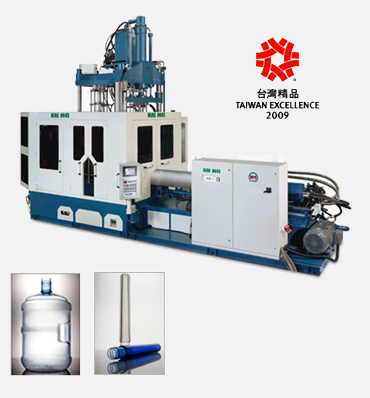

Kai Mei Plastic Machinery Catalog

Major features and innovations of MIB 85-C INJECTION STRETCH BLOW MOLDING MACHINE are:

Video:

Machine Specification

| Model No. | UNIT | MIB 85-C |

| Screw Diameter | mm | 85 |

| Injection Capacity | cm3 | 1440 |

| Screw Heating Capacity | kw | 24.7 |

| Injection Clamping Force | ton | 61 |

| Injection Mold Daylight | mm | 580 |

| Blowing Mold Clamping Force | ton | 41 |

| Blowing Mold Opening Stroke | mm | 400-800 |

| Maxinum Blowing Air Pressure | kg/cm2 | 20 |

| Blowing Air Pressure | kg/cm2 | 14 |

| Operation Air Pressure | bar | 8 |

| Hydraulic Motor | hp | 50HP+100HP |

| Machine Size(L x W x H) | mm | 9,500 x 4,000 x 5,500 |

| Machine Weight | ton | 15.0 |

*All specifications and designs are subject to change without notice.

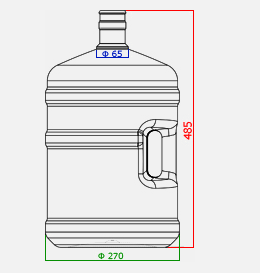

- Approximate Capacity (Gallon) 5 G

- Neck Diameter 65 mm

- Body Diameter 270 mm

- Height Diameter 485 mm

KM Model NO.

KM-PBS-405VS, TC, TL / KM-PBS-505VS, TC, TL / KM-PBS-605VS, TC, TL / KM-PBS-705VS, TC, TL / KM-PBS-905VS, TC, TL

- TC series: for the production of two-color plastic containers or toys

- TL series: suitable for 2-layer bottles (ex. Cosmetic bottle only outside layer with pearl or color & made of virgin material)

- Double-head or 3-layer machine can be delivered to order

Machine Specification

| MODEL NO | UNI | PBS-405S-TRL | PBS-405D-TRL | PBS-405S-QL | PBS-405D-QL | PBS-405S-FL | PBS-405D-FL | ||||||||||||||

| Mould center distance | mm | 120 | 120 | 120 | |||||||||||||||||

| Product max. capacity | C.C. | 80-1000 | 80-400 | 80-1000 | 80-400 | 80-1,000 | 80-400 | ||||||||||||||

| Min./Max. dia. Of product | mm | 30-100 | 20-80 | 30-100 | 20-80 | 30-100 | 20-80 | ||||||||||||||

| PE | GLUE | EVOH | PE | GLUE | EVOH | PE | PE | GLUE | EVOH | PE | PE | GLUE | EVOH | PE | GLUE | EVOH | PE | GLUE | EVOH | ||

| Screw Diameter | mm | 45 | 30 | 30 | 45 | 30 | 30 | 40 | 40 | 30 | 30 | 40 | 40 | 30 | 30 | 45 | 30 | 30 | 45 | 35 | 30 |

| Screw L/D Ratio | 24/1 | 26/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 26/1 | 24/1 | |

| Inverter Motor | HP | 10 | 5 | 5 | 10 | 5 | 5 | 7.5 | 7.5 | 5 | 5 | 7.5 | 7.5 | 5 | 5 | 10 | 5 | 5 | 10 | 5 | 5 |

| Capacitor for barrel | KW | 3.8 | 1.8 | 1.65 | 3.8 | 1.8 | 1.65 | 3 | 3 | 1.8 | 1.65 | 3 | 3 | 1.8 | 1.65 | 3 | 1.8 | 1.65 | 3.8 | 2.5 | 1.8 |

| Screw Speed | r.p.m | 20-65 | 20-65 | 20-65 | 20-65 | 20-65 | 20-65 | ||||||||||||||

| Extruding capacity | Kg/hr | 24 | 24 | 24 | 24 | 24 | 24 | ||||||||||||||

| Capacitor for die head | KW | 3.5 | 4.8 | 3.8 | 5.2 | 4 | 5.7 | ||||||||||||||

| Clamping Force | Ton | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | ||||||||||||||

| Hydraulic Drive Motor | HP | 5 | 5 | 5 | 5 | 5 | 5 | ||||||||||||||

| Air Pressure | Kg/cm² | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | ||||||||||||||

| Air Consumption | L/min | 500 | 500 | 500 | 500 | 500 | 500 | ||||||||||||||

| Total Electric Power | KW | 30 | 31 | 36 | 37 | 29 | 33 | ||||||||||||||

| Average Energy Consumption | KW | 24 | 25 | 29 | 30 | 24 | 26 | ||||||||||||||

| Machine N.W. | Kg | 2,700 | 2,700 | 2,700 | 2,700 | 2,700 | 2,700 | ||||||||||||||

| Machine G.W. | Kg | 3,200 | 3,200 | 3,200 | 3,200 | 3,200 | 3,200 | ||||||||||||||

| MODEL NO | UNI | PBS-605S-TRL | PBS-605D-TRL | PBS-605S-QL | PBS-605D-QL | PBS-605S-FL | PBS-605D-FL | ||||||||||||||

| Mould center distance | mm | 160 | 160 | 160 | |||||||||||||||||

| Product max. capacity | C.C. | 1000-5000 | 450-1800 | 1000-5000 | 450-1800 | 1000-5000 | 450-1800 | ||||||||||||||

| Min./Max. dia. Of product | mm | 75-200 | 50-110 | 75-200 | 50-110 | 75-200 | 50-110 | ||||||||||||||

| PE | GLUE | EVOH | PE | GLUE | EVOH | PE | PE | GLUE | EVOH | PE | PE | GLUE | EVOH | PE | GLUE | EVOH | PE | GLUE | EVOH | ||

| Screw Diameter | mm | 60 | 35 | 35 | 60 | 35 | 35 | 55 | 45 | 35 | 35 | 55 | 45 | 35 | 35 | 60 | 35 | 35 | 60 | 40 | 35 |

| Screw L/D Ratio | 24/1 | 26/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 26/1 | 24/1 | |

| Inverter Motor | HP | 20 | 5 | 5 | 20 | 5 | 5 | 15 | 10 | 5 | 5 | 15 | 10 | 5 | 5 | 20 | 5 | 5 | 20 | 7.5 | 5 |

| Capacitor for barrel | KW | 6.3 | 2.5 | 2.325 | 6.3 | 2.5 | 2.325 | 5.8 | 3.8 | 2.5 | 2.325 | 5.8 | 3.8 | 2.5 | 2.325 | 6.3 | 2.5 | 2.325 | 6.3 | 3.25 | 2.325 |

| Screw Speed | r.p.m | 20-65 | 20-65 | 20-65 | 20-65 | 20-65 | 20-65 | ||||||||||||||

| Extruding capacity | Kg/hr | 55 | 55 | 55 | 55 | 55 | 55 | ||||||||||||||

| Capacitor for die head | KW | 6 | 10 | 7 | 11 | 8 | 12 | ||||||||||||||

| Clamping Force | Ton | 9 | 9 | 9 | 9 | 9 | 9 | ||||||||||||||

| Hydraulic Drive Motor | HP | 15 | 15 | 15 | 15 | 15 | 15 | ||||||||||||||

| Air Pressure | Kg/cm² | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | ||||||||||||||

| Air Consumption | L/min | 700 | 700 | 700 | 700 | 700 | 700 | ||||||||||||||

| Total Electric Power | KW | 51 | 55 | 59 | 63 | 53 | 60 | ||||||||||||||

| Average Energy Consumption | KW | 40.8 | 44 | 47.2 | 50.4 | 42.4 | 48 | ||||||||||||||

| Machine N.W. | Kg | 5,100 | 5,100 | 5,100 | 5,100 | 5,100 | 5,100 | ||||||||||||||

| Machine G.W. | Kg | 5,800 | 5,800 | 5,800 | 5,800 | 5,800 | 5,800 | ||||||||||||||

| MODEL NO | UNI | PBS-905S-TRL | PBS-905D-TRL | PBS-905S-QL | PBS-905D-QL | PBS-905S-FL | PBS-905D-FL | ||||||||||||||

| Mould center distance | mm | 250 | 250 | 250 | |||||||||||||||||

| Product max. capacity | C.C. | 10,000-20,000 | 1,500-5,000 | 10,000-20,000 | 1,500-5,000 | 10,000-20,000 | 1,500-5,000 | ||||||||||||||

| Min./Max. dia. Of product | mm | 150-300 | 120-200 | 150-300 | 120-200 | 150-300 | 120-200 | ||||||||||||||

| PE | GLUE | EVOH | PE | GLUE | EVOH | PE | PE | GLUE | EVOH | PE | PE | GLUE | EVOH | PE | GLUE | EVOH | PE | GLUE | EVOH | ||

| Screw Diameter | mm | 90 | 45 | 45 | 90 | 45 | 45 | 75 | 65 | 45 | 45 | 75 | 65 | 45 | 45 | 90 | 45 | 45 | 90 | 55 | 45 |

| Screw L/D Ratio | 24/1 | 26/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 26/1 | 24/1 | |

| Inverter Motor | HP | 60 | 10 | 10 | 60 | 10 | 10 | 40 | 20 | 10 | 10 | 40 | 20 | 10 | 10 | 60 | 10 | 10 | 60 | 15 | 10 |

| Capacitor for barrel | KW | 14.1 | 4.1 | 3.8 | 14.1 | 4.1 | 3.8 | 10 | 6.7 | 4.1 | 3.8 | 10 | 6.7 | 4.1 | 3.8 | 14.1 | 4.1 | 3.8 | 14.1 | 7.3 | 3.8 |

| Screw Speed | r.p.m | 20-65 | 20-65 | 20-65 | 20-65 | 20-65 | 20-65 | ||||||||||||||

| Extruding capacity | Kg/hr | 130 | 130 | 130 | 130 | 130 | 130 | ||||||||||||||

| Capacitor for die head | KW | 12 | 16.2 | 13 | 17.5 | 14.5 | 19 | ||||||||||||||

| Clamping Force | Ton | 21 | 21 | 21 | 21 | 21 | 21 | ||||||||||||||

| Hydraulic Drive Motor | HP | 30 | 30 | 30 | 30 | 30 | 30 | ||||||||||||||

| Air Pressure | Kg/cm² | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | ||||||||||||||

| Air Consumption | L/min | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | ||||||||||||||

| Total Electric Power | KW | 117 | 121 | 120 | 125 | 119 | 131 | ||||||||||||||

| Average Energy Consumption | KW | 93 | 97 | 96 | 100 | 95 | 104 | ||||||||||||||

| Machine N.W. | Kg | 10,600 | 10,600 | 10,600 | 10,600 | 10,600 | 10,600 | ||||||||||||||

| Machine G.W. | Kg | 12,100 | 12,100 | 12,100 | 12,100 | 12,100 | 12,100 | ||||||||||||||

KM Model NO. PBA-210 (A/B)

These machines are high cycle pneumatic blow-molding machines, suitable for popsicles & wide variety small size bottles. Specifications:- PBA-210: Suitable for producing ice pops, toys.

- PBA-210A: Suitable for producing small size screw neck bottles.

- PBA-210B: Suitable for producing small size two-color bottles, toys.

- This series of machines are fully pneumatic driven featuring high speed motion. Especially ideal for providing small containers and popsicle containers.

- This series features high production output. highly economic efficiency and easy maintenance.

Mold Platen Dimensions

| NO. | Max. | Min. | A | B | C | D | E | F | G |

| PBA-210 | 240 | 80 | 230 | 46 | 138 | 20 | 90 | 130 | 11 |

Principal Specifications

| Model No. | UNIT | PBA-210(PE) | PBA-210A(PVC) | PBA-210A(PE) | PBA-210B |

| Max. product capacity | C.C. | 20~300 | 20~300 | 20~300 | 20~300 |

| Min. / Max. dia. of product | mm | 10~80 | 10~80 | 10~80 | 10~80 |

| Screw diameter | mm | 40 | 40 | 40 | 35x35 |

| Screw L/D ratio | 22/1 | 22/1 | 22/1 | 22/1 | |

| Inverter motor | HP | 5 | 5 | 5 | 3x2 |

| Screw rotating speed | r.p.m. | 15~50 | 15~50 | 15~50 | 15~50 |

| Extruding capacity | kg/hr | 14 | 16 | 14 | 10x2 |

| Outer diameter of die mouth | mm | 40 | 46 | 40 | 55 |

| Open close daylight | mm | 80~240 | 80~240 | 80~240 | 80~240 |

| Dry cycle | sec. | 2 | 2 | 2 | 2 |

| Pressure of air | kg/cm² | 4~6 | 4~6 | 4~6 | 4~6 |

| Compressed air consumption | L/min | 400 | 600 | 500 | 600 |

| Total power consumption | kw/h | 8 | 9 | 8 | 10 |

| Machine net weight | kg | 500 | 600 | 600 | 700 |

| Gross weight | kg | 900 | 1000 | 1000 | 1150 |

| Machine dimensions | m | 1.8x1.6x1.9 | 1.8x1.6x1.9 | 1.8x1.6x1.9 | 1.8x1.6x1.9 |