Public

Kornelis Brochures

Kornelis Catalog

Kornelis Gallery

Kornelis Locations

Kornelis News

Kornelis Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Kornelis is proactive when it comes to sustainability. The Dutch caps and closures manufacturing company takes CSR very seriously and has been implementing changes across the business in its facilities, production lines, and its finished products to close the gap even further.

The new Kornelis Caps & Closures factory was built to have the lowest possible footprint and produce closures that can be separated and recycled the closures produced are perfectly separable and recyclable, but the company is not stopping there.

Craftsmanship & smart technology

Since 2016 the company has been one of the most modern closure factories in Europe and proactively implemented Research and Development to ensure that it stays at the forefront, always seeking out the next steps.

As a family business, employee development is critical to the company's success. People are central and employees are developed to ensure that motivation and creativity are matured for the benefit of both corporate and social impact.

As a result, the company benefits from a keen eye for sustainability, a positive impact, and the incorporation of smart technology alongside sustainable processes to ensure that staff motivation is high and that waste is at the absolute minimum.

Industry 4.0

The application of Industry 4.0 across manufacturing has proven to be highly beneficial, with thought sensors registering the injection molding processes and all the surrounding variables. This smart, digital technology has enabled Kornelis to have the lowest possible footprint in its new hall and production facilities.

The facilities feature solar panels and underground pipes. There are also modern, electric machines to ensure that energy requirements are very low. Furthermore, production by-products are avoided to ensure that any waste produced is absolutely minimal.

With the company's in-house production maintaining such a high level of sustainability, Kornelis has extended the requirements across its supply chain to further its reach in its quest to close the sustainability gap.

"We first tackled sustainability across our site and in our production. But, production is a 2-part process: Pre-consumer and post-consumer. Having optimized everything as much as possible in-house, we've taken a step back to look at the complete picture and are now focusing on our supply chain because if our suppliers can be more sustainable in their production, it has a knock-on effect of making our own products even more sustainable", comments Dave Busstra, Sales & Marketing Director at Kornelis.

The bigger picture

Sustainability is not one-size-fits-all and the global topic of sustainability is a highly emotional one. To ensure that Kornelis stays on track, the company is led by facts to ensure that its customers benefit from full disclosure about the sustainability of its products. As such, it is not the market placing demands upon Kornelis, rather Kornelis leading its customers to sustainable products and solutions.

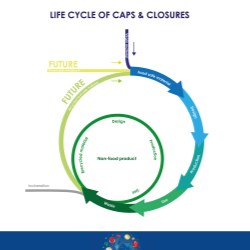

Kornelis' 2020-2025 business plan is very clear about how green its products currently are and how green they can become. The company has already implemented reduced weight products which have a lower carbon footprint through the use of less production material, in addition to reduced emissions for their transportation. There are also mono-material products that can be recycled after use. Recyclability is considered in the first part of a product's manufacture to ensure that the material is reused and has a second life as a new product.

"Within the next 5-10 years, we are working to ensure that all of Kornelis' caps and closures are manufactured from a sustainable raw material that is 100% recyclable. We want to contribute to a circular economy. We want more", says Ytsen de Boer, Technical Projects Leader. "Consumers have been putting our customers under pressure, so we are working hard to resolve problems over which we have influence, such as lightweighting, recycling, etc."

In a Life Cycle Analysis (LCA) commissioned by Kornelis and completed by independent experts, the numbers prove that plastic is a good packaging choice for many products because it is recyclable and there is little energy required for transportation or for recycling. Plastic offers many exceptional qualities.

Kornelis is aware, however, that although 70% of its turnover is in the Benelux area, over half of that product is exported, which leads the company in its search for sustainable raw materials that can be injection molded and maintain the same properties. Also on the horizon is the EU directive for tethered beverage caps from 2024, therefore Kornelis is researching and developing options whereby its non-beverage caps and closures can also remain attached to the packaging.

"We are always looking for a balance between sustainability and ease of use for the consumer whereby we are balancing on a tightrope of conflicting demands. And yet we continue taking steps forward to be even more sustainable", concludes de Boer.

.jpg)

.png)

.jpg)

.png)