If this is your company, CONTACT US to activate Packbase™ software to build your portal.

The major interest of this innovation, which is the subject of international patents, resides in the combination of the advantages of the aluminum, the best known barrier to date, with the easy filling of a cylindrical open pouch.

"Yes! We filled up this year", said Louis Khoury, the Marketing and Sales Business Manager of LABLABO, "Cattier, B com Bio, Huiles et Beaumes, Olivier and Co, Sicobel, Pure Altitude, Chic et Nature, YSL, Stella McCartney, NUXE and of course the rewarded line for Origins, by the Estée Lauder companies. This is an endless list of the most prestigious brands on the market."

Shall they talk about the Lablabo's airless pouch phenomenon?

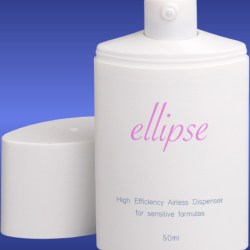

"We chose this type of airless system because it prevents air from reentering the package after the product has been dispensed", explains Alan Bodker, the Executive Director of Global Packaging for Origins, in the CPC magazine.

Fortified by their success with their airless pouch system, LABLABO continue on this path with their new airless EasyFoil: A bottle fitted with a pouch consisting of an aluminum multilayer film rolled up and welded around a superior ring and an inferior bottom cap both of which are produced in a thick plastic material. The film is composed of an exterior PET layer and an interior PP or PE layer, wrapping a central aluminum layer of 12 microns in thickness.

Depending on the nature of the product to be dispensed, the internal layer choice will be either PP or PE, the ring and bottom cap being of course produced in the same material with a sufficient thickness to provide a perfect barrier, especially against Oxygen or UV.

However, LABLABO never do things half way, this innovation is coupled with the industrialization of the self-sealing actuator which will strengthen the EasyFoil with an outstanding performance against loss of weight, and O2.

The major interest of this innovation, which is the subject of international patents, resides in the combination of the advantages of the aluminum, the best known barrier to date, with the easy filling of a cylindrical open pouch.

Indeed, whereas a traditional aluminum pouch, i.e. flat, would require special equipment and very delicate handling during the filling process, EasyFoil offers a ridiculously easy filling method since it can be achieved with any standard machine, simply by gravity.

This aluminum pouch technology can now be introduced on all production and filling sites without any constraints.

Is LABLABO moving from being "a creative airless" into representing "the perfect airless"?

Visit them at Beyond Beauty Paris, stand D79.