Public

Lameplast 3D Catalog

Lameplast Catalog

Lameplast Documents

Lameplast Gallery

Lameplast Locations

Lameplast News

Lameplast Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

The future of packaging is looking increasingly greener and more practical. That's why Fratelli Carli's Mediterranea brand has chosen the Lameplast Group's injection-molded single-dose container in Green Polyethylene (Bio PE) for its new 'Olive' cosmetic line.

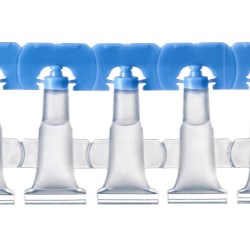

For the brand, the Italian company has produced a strip of five 10ml sized white single-dose reclosable containers, printed with bioplastics of vegetable origin and personalized with pad printing for the travel kit benefiting five products: tonic milk, multi-active face cream, active hand cream, moisturizing body fluid and bath cream.

The new Mediterranea Olive line combines Fratelli Carli experience with the excellent cosmetic properties of the Olive tree and its extracts to present immediately absorbable products that are pleasantly sensorial with effective anti-age action.

Nature gives beauty a hand but demands respect. That's why the Mediterranea brand has decided to present its products, formulated with strictly natural ingredients, in an ecological pack able to reflect sustainability and respect for nature. The strip, the upshot of years of research by the Lameplast Group into green, sustainable, renewable and recyclable packaging, is produced from sugarcane ethanol and not from petroleum.

Today, the Lameplast Group is able to present an entire range of bioplastic containers. Biopolymers can now be used to make single and multi-dose containers for food, cosmetic and personal care products.

Why use bioplastics?

There are benefits for the environment as well as benefits for a company's "green" projects. Unlike traditional plastics, Green Polyethylene is not obtained from petroleum, but from sugarcane ethanol. The result is a singular plastic with the same technical specifications, appearance and versatility as traditional polyethylene, but with many other strong points:

- It is sustainable – The sugar cane crops used to make Green Polyethylene comply with the very highest sustainability standards defined in the Braskem Code of Conduct.

- It is renewable – Green Polyethylene is made from ethanol produced from “non-GMO” sugar cane grown in Brazil, a renewable raw material.

- It cuts greenhouse gas emissions – Sugar cane traps the CO2 in the atmosphere at each growth cycle, thus helping to reduce the negative effects of greenhouse gases

- It is 100% recyclable – Green Polyethylene is recyclable in the same recycle chains as traditional polyethylene obtained from fossil sources.

The Bioplastic used by Lameplast Group is Braskem I'M GREEN™ POLYETHYLENE, distributed by FKuR Kunststoff GmbH.