Public

Mecmesin Catalog

Mecmesin Certificates

Mecmesin Documents

Mecmesin Locations

Mecmesin News

Mecmesin Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

The importance of visually-appealing packaging is obvious, but just as important are the quality, functionality and integrity of the utilised materials for consumer confidence and brand reputation. We caught up with Declan Tierney, Sales Director at Mecmesin, to learn about the key role their equipment plays in ensuring your packaging stands up to the test.

Mecmesin is a UK-headquartered company, but could you tell me a bit about your presence further afield?

Mecmesin's headquarters is based in Slinfold, near Horsham in West Sussex. The company has undergone significant global expansion and has subsidiary companies in France, Germany, the USA, China and Thailand. In addition, Mecmesin has a global network of distributors in more than 50 countries, each able to provide technical expertise and after-sales support to customers locally.

Can you summarise briefly the role Mecmesin plays within the packaging industry?

Mecmesin is a leading designer and manufacturer of force and torque test equipment, with over 40 years' experience in this field. Our precision test instruments and measurement systems are accurate and reliable, with applications perfectly suited to the quality control challenges of all packaging solutions: protecting the contained product whilst remaining easy to open by the end user.

We operate under ISO 9001 quality standards, so our products are used to guarantee the quality of components, materials and finished products, from factory floor through to the R&D laboratory, in many industries.

And what are the main benefits that users of Mecmesin test equipment experience?

Our test equipment enables businesses to maximise their production, optimise their machinery parameters, ensure their products are fit-for-purpose and guarantee the consistency of their materials' performance. The testing process also allows companies to identify any possible defects, minimising rejects and reducing the costs associated with excess wastage further down the line.

Furthermore, our equipment aids users in complying with internal and international test standards. Gaining an in-house capability for quality assurance processes, rather than out sourcing, is a major cost reduction benefit we see for many customers.

The packaging industry is obviously made up of diverse segments, which in turn use a plethora of different materials. There must be a variety of needs for which you need to cater?

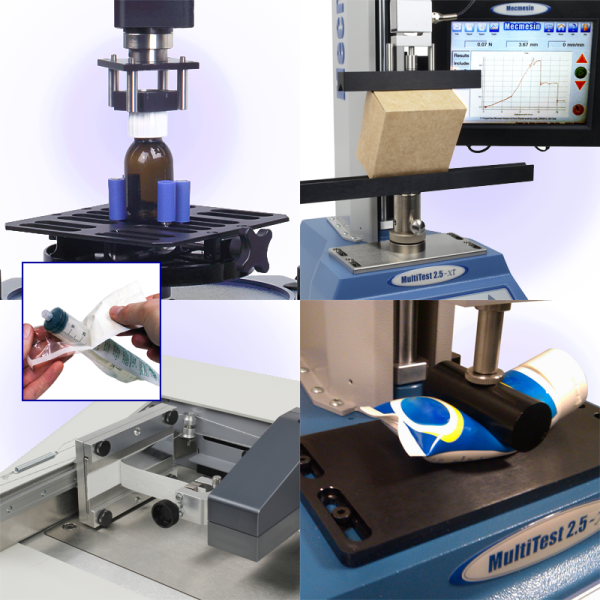

This is true. By offering simple hand-held instruments to fully-comprehensive computer-controlled test systems, we design products to suit many different test applications, budgets and changing needs.These include force gauges, torque gauges, tensile and compression testing systems, torque testing systems and software.

We offer three distinct levels of test system, which includes simple-to-use motorised systems, semi-automated console-controlled systems and fully-featured computer-controlled systems.

Mecmesin also supplies a range of application-specific testers, designed to test to international standards for a diverse range of distinct test applications, such as coefficient of friction (COF), pull testing of wire terminal joints and cables, page pull strength of books, automated bottle closure testing, testing muscle strength and measuring sprayed concrete strength.

In addition to our standard products, Mecmesin application engineers can design and manufacture bespoke test solutions to meet the needs of unique applications with specific criteria. These typically include vacuum fixtures for preform packaging, cap mandrels to fit specific designs, grips for control of devices with moving parts, jigs for bending awkward or large items, fixtures for torsion springs, guards and containment, and many others.

So, your versatility for packaging companies is clear. Why else should people choose to do business with Mecmesin instead of a competitor?

The focus of the company has always been to provide high quality test solutions which are an affordable alternative to the many higher-priced systems available; enabling small and large businesses alike to undertake quality control checks on their products without compromising on precision and accuracy. The rugged design of these systems means they can withstand tough factory conditions and perform tests at the point of production rather than having to use expensive laboratories to ensure consistent manufacture.

Do you have any new equipment, either released recently or in development?

We recently launched the first of a new generation of torque testers, the Vortex-dV Digital Motorised Torque Tester, with a focus on precision control. It offers unparalleled control at the level of the most affordable entry-level systems.

It is suitable for many components, including caps and closure testing, screw-fit cosmetics, hinges, handles and springs, as well as rotating component parts.

http://www.mecmesin.com/vortex-dv-torque-tester

Similarly, but on the force testing side, we have our new MultiTest-dV Motorised Force Tester. It is a universal testing machine (UTM) with multifunction operation, and is also an entry level system with a focus on precision control.

It is ideal for a wide range of force testing, such as compressive bend, tensile testing, top-load, insertion and withdrawal, peel and adhesion, pull-off and puncture.

http://www.mecmesin.com/multitest-dv-precision-control-force-testers

Finally, what types of companies have benefited from Mecmesin's test equipment?

Given the versatility of our products, we work with a wide range of companies across the packaging industry, including companies in Cosmetics and Personal Care; Fabric and Textiles; Food; Medical and Veterinary, Adhesives and Coatings.

Some well-known names include the likes of Bacardi, Britvic, Coca Cola, Danone, Heinz, Nestle, Princes Foods, Tetra Pak, L'Oréal, Dior, Johnson & Johnson, P&G and 3M.

.png)

.jpg)