Public

Mecmesin Catalog

Mecmesin Certificates

Mecmesin Documents

Mecmesin Locations

Mecmesin News

Mecmesin Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Specification

A major global supplier of medical gas devices and components required quality control tests to assess part of a new product. One of their components, a 5ml pressurised aluminium cylinder filled with helium gas, is incorporated into a needle-free powder intradermal analgesic injection system for children.

To ensure consistent quality and good manufacturing practices, the supplier needed to test the break-off force of the aluminium cylinder cap at its stem. The company used to perform the test manually, but required a motorised system, which could perform the test at a consistent speed to gain better result accuracy.

Solution

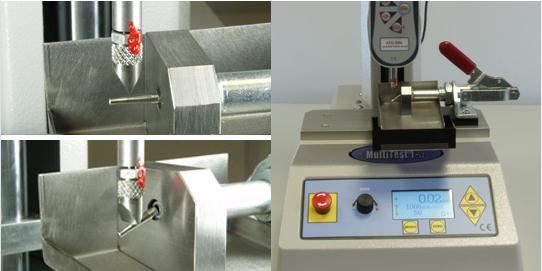

Mecmesin provided a MultiTest motorised test system with an Advanced Force Gauge (AFG), a chisel point accessory, to break-off the cap, and special fixturing to securely hold the sample in place.

It was vital that the sample would always break at the same point, therefore, a special cantilever-operated sample holder was manufactured. This enables each cap to be loaded and precisely positioned using the same amount of pressure each time, which minimises variability.

A specially designed non-adjustable base plate also ensures the sample and fixturing remain static for consistency during and between measurements. Tests are performed at a constant speed of 50 mm/min, with the force displayed and recorded by the AFG.

.jpg)