Public

Obeikan MDF Blog

Obeikan MDF Catalogue

Obeikan MDF Gallery

Obeikan MDF Locations

Obeikan MDF News

Obeikan MDF Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

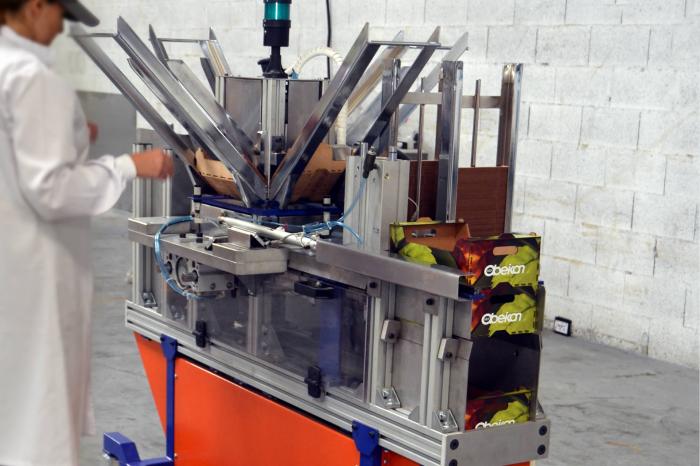

Obeikan MDF uses its own patented assembly machines which provide high performance are based on the principles of pneumatic impact and do not require the use of glue nor staples or any other auxiliary material. These machines only consume electricity and compressed air and are very easy to operate, requiring little maintenance.

The machine can assemble up to 1,200 packs per hour, and have the capability of adjusting the operating speed to any production line. The machine automatically feeds the bottom and the side panels of the boxes, pressing them together until the panels are interlocking into each other forming a firm stable box.

Once assembled, the boxes integrate into the process of filling like any ordinary packaging solution. For interim storage, the assembly machines can be fitted with a box stacker unit saving manpower. At the end of the filling process, the boxes can be sealed with a lid, either by hand or by using Obeikan's lid applicator machine.

With the aim of minimizing transport and storage costs, Obeikan MDF boxes can be shipped unassembled, stacked flat on pallets.

Assembly machines designed to mount the boxes can be installed directly at the packing house, next to the place of packing. This system enables efficient storage, i.e. only the amount of boxes needed for the daily operation need to be assembled, while the rest can be stored unassembled saving significant amount of storage space.