Public

Phaba Srl Catalogue

Phaba Srl Catalogue - PDF Version

Phaba Srl Certificates

Phaba Srl Locations

Phaba Srl News

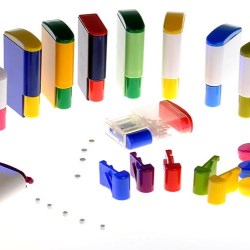

Phaba Srl Product Gallery

Phaba Srl Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Phaba, one of Italy's primary sources for numerous pharmaceutical and health-oriented packaging solutions, has recently upgraded its machinery to be able to offer better service and faster times to market.

According to Walter Cecchini, CEO at Phaba:

One of our primary goals with this upgrade is to increase factory automation as much as possible, thus reducing times to market. The new machinery also gives us the ability to assure a more stringent level of quality from our mechanized lines. We're investing in a lot of R&D projects at the moment, and our qualified experts are doing their utmost to react to market evolution. This will allow Phaba to reach a higher level of innovation and competitiveness.

Some of the new machines incorporated into Phaba's lines include new presses for the company's popular micro-enema kits as well as new assembly machines for talcum caps.

In order to move forward and renew its equipment, Phaba has also invested in a variety of process technologies. The firm has also engaged in detailed studies on new available technologies, projects concerning the development of automated machineries, and studies on attention to energy saving, all with the very specific goal of improving quality and productivity.