Public

TPG Packaging Locations

TPG Packaging News

TPG Packaging Presentation

TPG Packaging Products and Markets

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Independent family business TPG Packaging has been a pioneer of the printing and processing business for over 25 years. Maxence Allain discusses how the company is continuing to develop through investment and providing the most modern and efficient solutions for its customers.

Tell us about TPG...

TPG is one of the pioneers of the printing and processing of packaging cartons industry benefiting from both experience and knowledge across the breadth of the industry. The company was established in 1987 and since then has transformed the capabilities of UV offset printing.

Inspired by the strength of the company within the market, the Allain family purchased the business in the year 2000, and recognizing its potential, invested heavily in that first year. The strength of the business has continued to grow and yet maintaining its independence and savoir-faire from the beginning.

The company is now led by Jonathan and myself, and we too continue to develop the company along the same line, with the strategies already founded yet working with a modern take to respond to the needs of our customers at TPG.

What is the company's core business?

As I mentioned before, TPG is a pioneer of the UV offset printing technique. Our presses use ultraviolet or UV which allow the inks to dry during the printing process, eliminating the time required by traditional solvent-based inks and the use of setting powder.

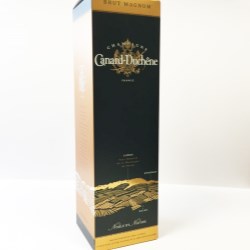

We have an extensive selection of machinery which includes flexo printing, hot stamping, embossing, cutting, folding and gluing as well as laminating. This means that we can cover a wide range of complex designs for folding cartons, cardboard sleeves, trays, cut-outs, coffrets and boxes. We can also prepare 4CC and 6CC boxes with paper or cardboard, metallic or transparent mediums and corrugated card (structured varnishing and/or hot stamping or embossing).

Our expertise also includes high-level finishes on materials using textures and tactile effects such as soft touch, pearl or glitter, not to mention playing with matt and gloss finishes and select varnishes for different looks. We have special inks - metallic, neon, glowing or even invisible - which can be used on different mediums to different effect.

Does the company have a particularly important ethos?

As a company, we keep our infrastructure highly optimized and ensure that our individual and company skills are highly developed in order to keep up with the ever-changing market.

Over the past 15 years, we have invested more than 15 million euros into the company, enhancing human resources, company processes and especially our body of machinery and equipment so that we can offer the best technology that results in the highest quality finishes to our customers.

The most recent investments this year include the integration of a cold foil in line into the press. In January 2016, a 13-group offset printing press; a cutting line in January 2015 and in March 2014 we incorporated a new folding-gluing line.

Another very important factor is the environment. We are continuously striving to reduce our impact upon the environment and because of this 70% of the paper and carton that we use is FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) certified meaning that it comes from sustainable sources and that the supply chain too meets best practice standards. Furthermore, we are working to increase this percentage with the close collaboration of our suppliers.

In what way is TPG Packaging unique?

At TPG Packaging, both our products and services are "haute couture" and can be identified under the banner of "made in France".

As a company, we control our entire production chain and unlike many other companies, our equipment is state of the art. Through the use of complex machinery, we can achieve a final render in a single pass which limits the amount of manipulation required and as such can be seen in the quality of the execution.

Within the industry, custom designs or made-to-measure is the norm. It is not uncommon for us to have customers visit us on-site so that they can see for themselves how we can meet their exclusive needs and requirement for an exceptional finish.

Over the past 2 decades, our experience has led us work with many important customers including; Carrefour supermarkets, Système U and Scamark, and within the catering sector, names such as Tipiak, Labeyrie, Marie and Guyader Gastronomie trust in us. Ultimately though, it is our luxury work for which we are really recognized: World class beauty brands like Kenzo, Yves Saint Laurent and Lancôme, and luxury names in wine and spirits including Rémy Martin, Martell, Hennessy, Johnny Walker, Pol Roger and Louis Roederer are all valued customers of ours.

What does the future hold for TPG Packaging?

We are expanding our services to incorporate the UK and US markets and our collaboration with Webpackaging has provided us with the perfect opportunity to start moving in this direction and open our communication up on a global basis. TPG has an excellent reputation with a noteworthy list of well-known global names as customers and expanding our geographical markets is the next clear step for the company.