If this is your company, CONTACT US to activate Packbase™ software to build your portal.

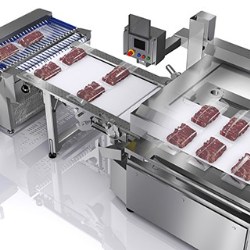

Using patent-pending technology, ULMA has developed a simple but brilliant solution to automate the feeding of a belt vacuum chamber on both sealing bars. Packages are sealed only on one end and prepared to be transferred to the buffering belt of the vacuum chamber with the open end facing both seal bars on the vacuum chamber.

A 90° transfer system pairs the packages to the buffering belt of the vacuum chamber so that both seal bars can be utilized. If the products are not small enough to be paired, an auto-detect system will load the product as a single item.

This automated system increases productivity and reduces labor costs. The packaging system is ideal for the meat and cheese industry.

.jpg)