Public

H.B. Packaging Catalog

H.B. Packaging Catalog 3D

H.B. Packaging Documents

H.B. Packaging Gallery

H.B. Packaging News

H.B.Packaging Locations

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

It seems that many companies are in the midst of expansion, and H.B. Packaging is a prime example of the current trend. Headquartered in China, the company is expanding internationally after updating its facilities and moving to a more automated production system. Further, the company is branching out into the food sector from its original focus on beauty and personal care packaging. We spoke to Ms. Shi Su Lin at H.B. Packaging to learn why now seems to be the time to go global.

What do you do at H.B.?

I’m the CEO of the company, I work out the partnerships and work to ensure out various teams have what they need to get the job done. We have extremely well-organized teams that each work on individual processes and projects. So, I coordinate each department to make sure things run smoothly and move forward.

What does HB focus on?

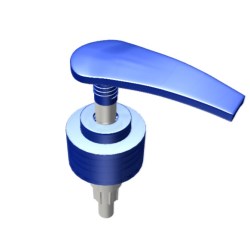

We are a manufacturer of packaging products. Unlike many other Chinese suppliers that seem to provide everything, we focus on caps, closures, and dispensing systems. Our expertise lies in dispensers and pumps and we want to provide perfect product service in this specific field. We work with clients to provide a number of services related to that specific sort of packaging. We focus on daily commodity packaging for the beauty and cosmetic markets, and mostly for toiletries. Since 2016 we have also been moving forward to provide packaging to food and beverage companies, and have had several successful projects. One in particular was to work with a honey producer company to provide caps specifically for that sort of product.

What sticks out as different, working with food companies?

The requirements for food packaging are much more rigorous than cosmetic packaging. Food packaging requires a better, cleaner factory environment and more detailed production management. Before branching out, we had to make sure we were well prepared. We have a food degree certificate for raw materials and our facilities are totally ISO 9001 certified.

Why the change?

We needed to branch out to remain competitive. There are different strategies for that. As I said, some companies offer a little bit of everything within a sector. We offer dispensers and closures, so it made sense for us to take our excellent products into different spaces, especially with brands seeking to try new things and differentiate themselves from competitors.

We offer customized designs, right from the initial concept. All our product developments are specifically geared toward caps, closures, and dispensers. That's the path we chose to succeed among competitors. There are so many possibilities within the cosmetic packaging industry, that we focus on one part of it, pursuing the perfect experience. We need to make sure customers receive the best quality possible.

What sorts of internal changes have been made for expansion?

In 2017, we're expanding our level of automation with eight more machine lines. And we've increased our automation production capabilities, it’s the best solution for maintaining consistently good quality and stable production rates. Full automation is excellent for high production capacities, and that leads to us being able to offer a better price, just by adopting large-scale automatic production in our facilities. Further, our new lines are much cleaner than traditional, manual production. There's no doubt that this will represent a leap in quality, something we can guarantee our customers.

We're also in the midst of replacing our old moulds. We're tooling fresh moulds for our stock products to be used at our upgraded production facilities. We're bringing back our regular items with a much higher level of quality and better pricing schemes.

What new items or services can you discuss? When will they be released?

We have a new cap with a silicon control valve inserted into it for lotion products. It’s a better solution for products that are of low viscosity, as it controls liquid flow efficiently and very effectively. We started designing it in 2016, and have received a lot of positive feedback from the customers we've shown it to. Now we have the R&D team developing more products along these lines, due to the popularity we've noticed.

We'll be showcasing our valve dispensers at numerous shows this year like China Beauty Expo in Shanghai, Cosmoprof Asia in Hong Kong, InterCharm in Russia, and the 24th edition of the Iran Cosmetic and Clean Product Exhibition. Not only are we seeking to foster growth in the food space as I've mentioned, we also want to keep growing our beauty and personal care distribution, and that means global expansion. That's one of the reasons we're going to these shows, to open up the international market and speak to more multinationals.

Is expansion your company's major change thus far?

Our stock products have a stable demand from the market, but when we update our tooling, moulding, and production facilities, we have to raise prices. Some of our original customers just cannot accept an updated price. In order to resolve this, we simply enhance the production rate to maintain good prices for our customers. The customers benefit from having original items with better prices and higher quality.

How is the company doing in general through expansion and improvement?

We are doing very well, and we plan to grow our product offering, to explore more packaging variations, to find more opportunities. We plan to acquire more types of customers by attending different exhibitions in a variety of different countries, not just within China.

Why outside of China?

The overall conditions in China are not favourable for Chinese companies, particularly with prices going up on raw materials. On the other hand, we benefit from the weaker US Dollar to RMB conversion rate. The world has the idea that labour here is very cheap, and that may have been true in the past, but rising costs and standard of living mean that labour is more and more expensive. Most Chinese companies have to deal with rapidly increasing labour costs, which is one of the reasons we're updating our factory to a fully automatic facility.