If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Flexible packaging design and manufacturing solutions for a wide range of industries, including pharmaceutical, medical device, confectionery, food and industrial. We pride ourselves on producing from quality materials, and our team of experienced packaging professionals has a strong track record for providing top tier customer service.

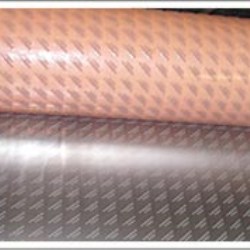

As a highly valued supplier to the Medical Device, Food and Confectionery Markets, one of our core specialties has been our polypropylene flow wrap. We produce flow wrap using OPP films because of its versatility, flexibility, and durability. Our films are light weight and offer superior printability. In addition, our films are moisture resistant and durable. We have the engineering experience and the machinery to help you develop the flow wrap packaging you need.

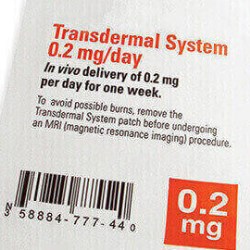

Apple Converting is the "Go To" contract printer for customer supplier backing film in the Transdermal Market. Apple Converting has mastered the ability to print successfully on on backing film for transdermal drug patches. We have the experience and expertise to handle the challenges involved in printing high-end quality on backing film. Our production facility is GMP compliant and we constantly strive to improve on our processes.

Apple Converting is proud to have been recommended by 3M to many of our key customers, and we have participated in multiple trials to show convertibility and printability on these challenging materials. To learn more about our backing film solutions or other services and products from Apple Converting, please contact us today or refer to the table below.

Apple Converting niche has been collaborating with our customers to solve their unique and creative packaging design challenges. Our packaging engineers and design team have developed an attractive foil lidding solution that simultaneously provides a tight seal at time of production and an easy peel for superior customer satisfaction.

Apple Converting understands how vital it is for packaging to be reliable and attractive. We are committed to partnering with our customers to create the visual branding you desire coupled with the reliability and performance you require.

We have developed a collaborative relationship with many pharmaceutical and healthcare customers that specialize in transdermal delivery systems. Our keen awareness of developing and supplying printed pouchstock solutions makes Apple an excellent partner. Apple Converting understands transdermal packaging applications that require materials with high chemical resistance (such as nicotine) and, in many cases, needs to be child resistant. All of these solutions are provided in our state of the art and GMP compliant production facility.

Apple Converting knows pharmaceutical and healthcare. Please contact us today to learn more about our products and services.

For packaging, the product size, shape and function will typically determine the ideal packaging method to choose. The medical device industry frequently utilizes flexible packaging that incorporates top sealing and bottom forming webs for unique structures. When the product requires a more rigid bottom tray, then flexible lidding film and foils are used for desired seal strength and barrier properties. In the food and industrial markets there are many variables and factors in choosing the right structure for the product.

Variables such as the machine type (such as horizontal and vertical form, fill, seal), the barrier properties needed to maintain freshness, the seal strength to ensure packaging integrity, and ease of opening for the consumer are just some of the factors that need to be taken into consideration. It can seem overwhelming when figuring all this out for a new product and when changes are being made for an existing product line. Our technical team can help you find the solution you need to create the right combination of materials and functionality.

Apple Converting has perfected confectionery twist wrappers that look and perform above expectations. Our in-house engineers and design team have developed a high quality printed wrapper with strip lamination that adheres to stringent tolerance requirements. Our product keeps candy fresh and opens smoothly every time. Thirty years of experience has given us the capability to provide exactly what our customers' demand.

Apple Converting confectionery wrappers utilize both a state of the art 9 color gravure and a 7 color flexographic press. Our ability to run water based gravure sets us apart from others in the field and highlights Apple Convertings desire to be environmentally responsible.