- This company is no longer trading

-

contact

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Several years after its success in North America, Bapco Closures has finally cracked the UK market, launching its innovative packaging in Marks and Spencer stores for the first time last month. Co-founder and Head of Operations, Peter McGeough, talks about the challenges of getting a technology business off its feet and introducing a revolutionary system to the sector.

Bapco Closures was set up back in 1998 having come up with an innovative solution to the leaky milk bottle top. The co-founders took a leap of faith, quitting their steady jobs at carton-maker Tetra Pak and pursuing their dream of building their own business. The plan involved buying a factory in the UK to make a closure that not only prevented milk from escaping, but also made it easier to open. Sounds simple on paper, but when the milk industry pulled its support for product development, we were forced to change our focus. It was a defining moment in Bapco Closures' history – but, as it turned out, a good one.

So we decided to look further afield. North America has a far bigger food and drink industry than the UK, so there was more scope for niche packaging technology over there. We found a market for the product, helping Del Monte to switch to a wide mouth polypropylene (PP) container with an easy open 82mm closure – followed shortly by the leading Tropicana brand to bring a unique oval hinged closure to the market. And after many a sleepless night, we managed to secure £4m worth of investment to build a factory in the US. It was a huge challenge but we wanted to prove to the dairy industry that it was wrong and, after eight years of trying to get someone to buy our idea, we were determined to make it work.

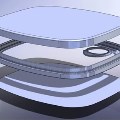

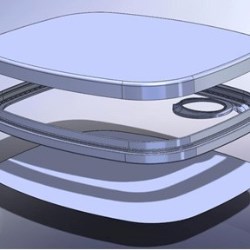

Bap Technology

The basic product is Bap Technology – an innovative two-part injection-moulded closure system that features an overcap and spout with an integrated fused foil laminate. Once liquid is filled into a container, the closure is positioned and induction-welded into place. The foil provides an absolute seal, securing leak-proof packaging. Since the foil traps the vacuum, rather than the overcap, it is also easier to twist off or simply flip open.

Having succeeded in North America, we turned our attention to the UK market.

Making in-roads in the UK

There were several challenges in cracking the UK market. Firstly, most retailers use separate manufacturers for containers and lids but Bapco Closures becomes part of the container with its closure system. It can take weeks – months even – to talk through the technological differences with product development and marketing teams, convincing them of the benefits of moving away from traditional packaging and changing both the jar and closure system.

Secondly, changing consumer perceptions requires a great deal of effort. I have been in the packaging industry long enough to realise that consumers know what they like and like what they know. Glass packaging has been around for years, so it is understandable that retailers and manufacturers are wary of changing to plastic packaging, which Bap Technology currently relies on. People are familiar with glass, they understand exactly how it opens and closes, as well as its limitations, and therefore feel comfortable purchasing it.

The breakthrough

Despite many hurdles, by working closely with European manufacturer RPC Group, we were able to crack the UK market for the first time this year. We now provide G's Marketing for the Marks and Spencer brand with a unique closure system and plastic container that matches the functionality of its old glass packaging. Even better, the range is 80% lighter.

The easy-opening feature of the Bap Technology - with its spiral ring pull mechanism which reduces the force required to open the foil closure - was extremely attractive to G's Marketing for its new Marks and Spencer pickles range, which hit shelves in September. It is a great achievement for Bapco Closures after 12 years in the business and one we’re particularly proud of.

Whilst the battle isn't over yet, it's encouraging to see a leading UK retailer like Marks and Spencer continually looking to improve packaging functionality for its customers. It is true that you need a lot of tenacity to work in the packaging industry to get past the stream of rejections that are par for the course. But if you have a great product and the determination to succeed, you can make it.