- This company is no longer trading

-

contact

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Peter McGeough, co-founder and Head of Operations at Bapco Closures, discusses the importance of innovative closure design. His contention that caps and closures receive less attention than containers is a valid one - read on to disover what implications this attitude has.

Caps and closures can sometimes play second fiddle to the primary pack design, with less time and resources spent on developing new solutions and more time on developing the pack itself. However, the choice of closure is one of the most important aspects of the entire package, allowing more flexibility in the overall design and enabling soft drinks brands to add more value to their product.

The remaining constant

For many years, drink manufacturers have been married to one type of closure when it comes to bottle or carton design. Whilst there is a great variety in the shape and size of packs on the market, one thing remains constant; a circular screw top. It is surprising that an industry as innovative as this continues to take such a one-dimensional approach to the issue, because as everyone knows, packaging is one the most important parts of any successful product.

It's no secret that every successful product undergoes extensive research and development before its launch, with companies ensuring that every aspect appeals directly to its target audience. A lot of time and money goes into the design of new packaging so that it stands out on the crowded supermarket shelf and attracts all potential buyers. Despite this, the design process is still limited by the type of closure used on the end product.

Showing the cap and closure the same consideration as the container would ultimately offer more freedom and flexibility in the overall design and help brand owners add even more value to their products. However, it's not just about the look; packaging functionality is hugely important to the soft drinks industry as the end product must be userfriendly for a variety of age groups and households across the globe. Most 'family size' bottles require a closure that is easy to open and forms an effective seal each time it is closed.

At the same time, containers have to be able to stand and lie on a refrigerator shelf, whilst the product must be easy to pour. Whilst a standard screw top closure helps the pack overcome most of these issues, there is very little that manufacturers can do to improve the product’s overall functionality.

Having been involved in the packaging industry for over 20 years, I believe that the biggest innovations in drinks packaging will only come when there is a new approach to design. Manufacturers should start the process with the closure rather than just adding a screw top at the very end. The result will give much more freedom to the design team and will significantly improve product functionality. But how much difference can a closure really make?

Revolutionary closure

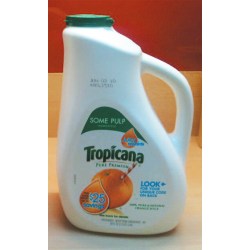

Back in 2007, we were approached by Pepsico who were looking to redevelop the packaging for its Tropicana Pure Premium orange juice container. When we first spoke to the company about the new closure concept, it was clear that they wanted to be creative with the design and that improving functionality was a key aspect.

A traditional screw top closure was tried and tested on other Tropicana products, but it simply couldn't deliver what was needed in terms of easy pouring on a larger bottle. We believed that the best solution was to create a brand new type of closure that would revolutionise the packaging and deliver huge benefits to the consumer and brand owner.

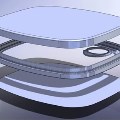

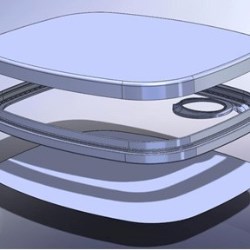

We decided to develop a closure that would fit a high density polyethylene (HDPE) container, be easy to open, help with the pouring process and

eliminate spillage. We drafted in a structural designer who created an innovative HDPE oval shaped hinged closure, with a slight lip. The chosen design utilised a reduced low profile oval neck on the container which facilitated opening the envelope for the bottle design which in turn allowed for a larger handle and a more curvaceous container shape.

By changing the shape of the closure, Tropicana was able to offer customers a distinctive container with a non-drip, intuitive, directional pouring mechanism that dramatically improved the flow of the liquid from the container.

What's more, to keep the product fresh, we welded a foil seal in place when the closure was manufactured which offered tamper evidence and, by using a ring pull, hugely improved ease of opening. From a consumer point of view, the package allowed them to pick up and pour much easier and store the bottle on both its side and bottom in a refrigerator.

Ultimately, the change to a HDPE easy-pour pitcher improved the functionality and shelf appeal of Tropicana's orange juice.

Functionality improved

The Tropicana project highlights the importance of innovation in packaging. By redeveloping something as simple as the closure, the company was able to alter the overall design in a variety of ways, improving the functionality tenfold. The soft drinks sector is one of the most innovative industries, but it needs to consider other shapes and types of closure that offer brand owners much more flexibility in the design process than a traditional screw top.

It is time for manufacturers to break the mould because the benefits of starting the design process with the closure cannot continue to be overlooked.