If this is your company, CONTACT US to activate Packbase™ software to build your portal.

- Global experts collaborate to improve recyclabilitiy of PE film

- Laser marking helps eliminate paper labels and ease recycling

- Project supports ‘Design for Recycling’ initative

- Click to retrieve high resolution image

Clariant has teamed up with pigment supplier Merck KGaA and resin producer SABIC to develop laser-marking technology and materials to ease the recycling process for flexible polyethylene (LDPE, LLDPE) packaging film. The results of the collaboration will be presented at K 2019, the international plastics trade fair being held on October 16 to 23 at Messe Dusseldorf in Germany.

“There is growing demand for clean, high-quality recycled PE,” explains Chun-Yip Pang, Clariant’s Global Product Manager Additive Masterbatches -- Laser, “and, while recycling rates for PE films continues to increase, there are still a number of challenges that need to be overcome. This collaboration is focused on eliminating the printing ink used for tracking, shelf-life, bar codes and other variable information that must be placed on almost any package on the market. Less ink means less contamination when it comes to recycling.”

The collaboration demonstrates a complete supply-chain solution for laser-marking of films. As the resin supplier, SABIC contributes the polymer technology that delivers the properties required in the film packaging. Besides that SABIC can supply a wide variety of polymers in it’s portfolio as certified circular polymer, contibuting even more to sustainable packaging. Laser-sensitive Iriotec® pigments and marking expertise are provided by Merck, while Clariant developed the additive masterbatch formulations for use in the film extrusion process.

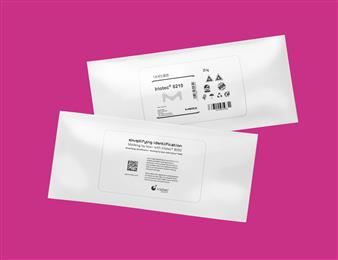

Because most plastics are transparent to the radiation used in the laser-marking process, the additives are necessary to achieve a visible reaction in the film. The marks are permanent and resistant to water, oil, grease or fatty foods. They can be applied to the surface of mono-layer film, or a laser-sensitive layer can be placed behind a laser-transparent surface layer. The additives provide excellent contrast and allow high-speed marking.

At K 2019, the collaborators will show several examples of laser-marked packaging films and pouches. In a presentation -scheduled for 2.30 pm and 4.30 pm, 22 October, 2019, in hall 8a / J11 – the influence of laser pigments to the recycling process will be presented as well as the marking process in the multilayer film produced by SABIC and Clariant.

Design for Recycling

Flexible PE is already well-accepted as an environmentally favorable packaging material. It is lightweight and versatile and, compared to other packaging it uses much less material. However, according to “Flexible Polyethylene Recycling in the EU,” a report published by Plastics Recyclers Europe (PRE), design-for-recycling principles suggest it is possible to go much further. It describes a recyclable pouch made of transparent or translucent, unpigmented, monomaterial LDPE or LLDPE. Here the label design via laser perfectly fits. As, unlike paper labels, there is no adhesives and no ink involved, which means less contaminants during the recycling process.

As brand owners work to increase the sustainability of their products and packaging, the use of laser-marking represents an attractive opportunity. As an example, Oliver Piening, Global Marketing Manager for Merck Industrial Pigments, points to coffee capsules. “There is tremendous pressure to ensure 100% recyclability of these little coffee pods, billions of which are used each year. Developers are eliminating aluminum and multi-layer, multi-polymer plastics structures and now they are working to eliminate the ink used in labeling. Many of these companies are looking seriously at laser marking.”

Mono-material, undecorated flexible PE packaging, of the kind envisioned by Plastics Recyclers Europe, is probably still years away from common use, Clariant’s Pang admits. “We want show people what is possible. Laser-marking is just one step on the journey to circularity but we believe that every step counts.”