If this is your company, CONTACT US to activate Packbase™ software to build your portal.

EyeC UK

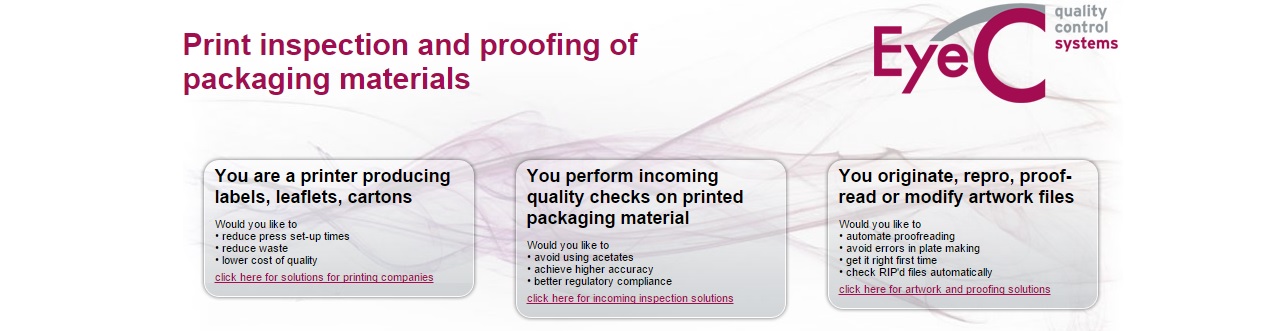

EyeC offers a range of print inspection and artwork comparison systems that cover the complete print cycle from artwork development, pre-press, press set up, outgoing QC and incoming materials inspection.

EyeC GmbH is a company focussed exclusively on producing solutions to ensure the accuracy and quality of printed packaging materials.

We work with you, the customer, to supply the right product and solution to meet your needs. We have products for checking text and graphics on labels, leaflets, folding cartons, cans, bottles and tubes. Whether you are an artwork studio, printer or a company performing checks of incoming packaging materials, our systems help you to save time, reduce scrap and improve the quality of your products and enhance your reputation with your customers.

We provide print inspection and proofing systems that cover the whole print cycle from artwork through pre-press, plate making, press setup, in line inspection, finishing and incoming materials inspection.

We put a lot of attention on training our staff and customers to ensure you get the most out of your acquisition. Our products have been developed in close cooperation with actual users with a strong emphasis on reliability, ease of use and conformance to applicable ISO, GMP, GAMP, and CFR regulations.

We also supply systems for incoming quality control for pharmaceutical packaging and branded goods manufacturers performing QC control on patient leaflets, folding cartons, labels, foils, cans and tubes. Applications include inspecting print on packaging for pharmaceutical, healthcare, medical devices, branded goods

The Proofiler Graphic checks artwork files typically a repro’d print ready file against the customer approved proof.

The Proofiler Content combines checking live text, graphics, Braille and barcodes in an artwork into a single examination. If adding or changing text in a revision causes the text to reflow, a graphical comparison is overwhelmed with deviations but Proofiler Content has no such issues.

The Proofiler includes a scanner for comparing the printed sheet against the customer signed proof. Our scanners range from A4 to A0 and beyond.

The ProofRunner is mounted on a press, rewinder or slitter to perform 100% inline inspection of printed packaging materials.

EyeC History

2003 Introduction of the EyeC Proofiler 400 off line print inspection system

2004 Development and installations of inspection Systems for cartons and labels

2005 Introduction of the EyeC Proofiler Braille for checking position and accuracy of Braille dots on pharmaceutical packaging. Introduction of the EyeC Proofiler 700 (with B2 scanner) for patient information leaflets, barcode inspection and verification.

2006 moved to larger premises. Launch of the EyeC ProofRunner inline print inspection system for narrow web presses and rewinders.

2007 100th system installed. Cigarette warning text control tool and the colour distance tools released.

2008 Extension of the Barcode testing to RSS and Data Matrix. Launch of the EyeC ProofRoller for inspecting print on tubes and cans

2009 moved to larger premises

2010 400th system installed. Introduction of the ProofRunner Wide for inspecting flexible packaging. Introduction of Carton Inspector which checks print on folding cartons after cut and crease. Won major contract to supply the Paragon Group with inline and offline inspection systems

2011 500th system installed

2012 600th and 700th system installed. Released ProofRunner inspection system integrated into Heidelberg Diana Folder Gluer. Released inline inspection system integrated into KBA sheet fed press. Won major contract to supply sheet inspection systems to Chesapeake Pharmaceutical Packaging sites

2014 Installed 1000th system