Public

Gerresheimer Brochures

Gerresheimer Gallery

Gerresheimer Locations

Gerresheimer News

Gerresheimer Product Catalog

Gerresheimer Publications "Update"

Gerresheimer Videos

Subsidiaries

Sensile Medical

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

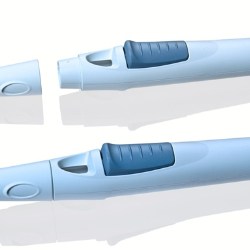

Auto-injectors are one of the more recent productsadded to Gerresheimer’s comprehensive range, when it secured a contract for them from a leading American pharmaceuticals manufacturer. Gerresheimer was chosen as supplier as a result of its special expertise in injection-related products and applications and the scope of services it offers. The auto-injector is composed of fourteen plastic components and three metal parts. The plastic components are produced by Gerresheimer, and then made into two subassemblies for final assembly and filling on the customer’s premises.

Gerresheimer’s range of prefillable syringes is further proof of its injection-related application competence. The syringes are made of glass and used around the world as packaging for pharmaceutical and biotech products. They are the first choice primary packaging material for vaccines and numerous other medications and also used for ophthalmic applications. Gerresheimer’s portfolio also includes ClearJect syringes made of COP (cyclic olefin polymer), a high-performance polymer, for special biopharmaceutical and oncological parenteral drugs.

The MultiShell vial by Gerresheimer proves thatexcellent barrier properties and glass-like transparency can be combined in one single product. It protects its content by way of a sandwich or multilayer structure composed of cyclic olefin polymer plus a polyamide layer as an oxygen barrier. This protects sensitive pharmaceuticals against oxidation and water vapor, and the polyamide oxygen barrier increases their shelf life. Gerresheimer has established a commercial production line and offer 2, 5, 10, 15, 50 and 100 ml vials. The installation of a multifunctional, automated packaging line will enable the packaging of different vials from bulk to ready-to-use.

.jpg)

.jpg)

.jpg)

.jpg)